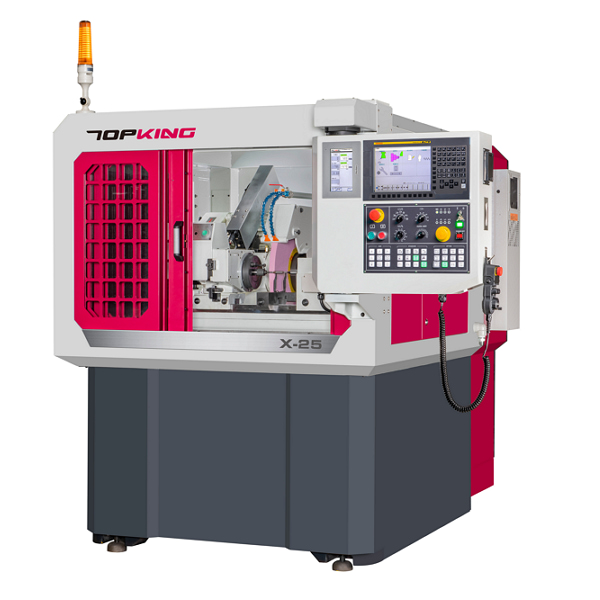

straight type G.W. | X-LM series

X-2540LM

plunge grinding - with linear motorINTRODUCTION

TOPKING's LM Series - CNC cylindrical grinder features a linear motor-driven cross-slide, enhancing machine rigidity and stability while reducing cycle times to meet the demands of high-efficiency, high-precision grinding. This series is ideal for machining high-accuracy components such as hydraulic valve parts, automotive components, and aerospace parts, delivering superior precision while optimizing productivity and process stability.

The LM Series also offers an optional synchronous workhead and tailstock with a dual-center synchronous drive system and an extendable spindle. This design streamlines workholding, minimizes fixture complexity, and eliminates the need for additional drive considerations. The extendable spindle overcomes tailstock travel limitations, increasing the grinding range to accommodate various workpiece sizes, enhancing flexibility, and maximizing machining efficiency.

| CAPACITY

Swivel Over Table: Ø270 mm

Distance Between Center: 400 mm

Max. Grinding Dia.: Ø250 mm

Max. Grinding Length: 400 mm

MACHINE FEATURE

USER FRIENDLY OPERATION SYSTEM

The built-in advanced CNC control system is equipped with GUI. The operator can divide the complex component into several grinding processes through the guidance of the graphic, and simplify the process editing of grinding, and dressing in a numerical way. No complicated programming (G code, M code) is required, and the most convenient operating environment is provided.

RIGID MACHINE BASE

■ High rigidity machine base made of Meehanite cast iron through annealing and aging treatment.

■ Slideway though high-frequency hardening and precision grinding process. Machine base with stable material and strengthen construction for deformation-free and outstanding wear resistance.

WORK TABLE

■ The work table is permanently bolted to the machine. The cross slide design is adopted to reduce the travels. It can improve working speed and precision stability.

.png)

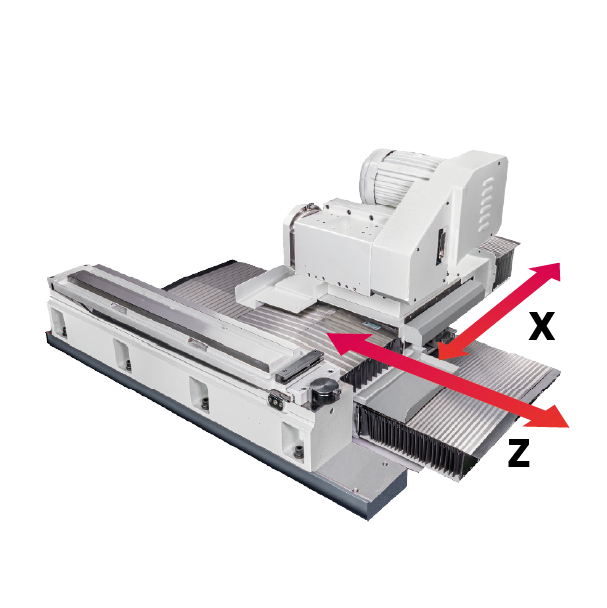

CROSS-SLIDER DESIGN

■ X axis and Z axis are design as cross-slider to reduce machine space.■ Two axes cover by enclosed telescopic covers. To protect the transmission structure and prevent contamination from grinding debris and coolant.

X-AXIS LINEAR MOTOR DRIVE

Featuring a cross-slide structure with a linear motor and high-precision linear guideways, this design effectively eliminates backlash. The standard X-axis full-closed loop control with an optical scale ensures fast and precise feed movements, achieving rapid traverse speeds of up to 15,000 mm/min. With a non-contact design using coils and permanent magnets, the linear motor minimizes wear, reduces maintenance needs, and lowers replacement costs.CARTRIDGE-TYPE GRINDING WHEEL SPINDLE

The cartridge-type grinding wheel spindle ensures stable contact, reducing vibration and wear-induced deviation for high-precision machining. Its design allows for easy wheel replacement and adapts to various grinding needs, enhancing efficiency and quality.

DUAL SYNCHRONOUS WORK SPINDLES (OPT.)

The LM Series offers an optional dual-drive workhead and tailstock with a dual-center synchronous drive system and an extendable spindle. This design simplifies workpiece clamping, reduces fixture complexity, and eliminates the need for additional drive considerations. The extendable spindle overcomes the travel limitations of the tailstock, allowing the equipment to quickly adapt to different workpiece lengths, minimizing tailstock adjustments during workpiece changes, enhancing processing flexibility, and meeting diverse manufacturing needs.

AUTOMATION APPLICATION

It can be integrated with external automation systems and includes an online measurement and acoustic collision prevention system for real-time feedback and data correction. The machine, powered by Kingge Technology's operating system, ensures stable high-quality output and reduces setup and line change time.

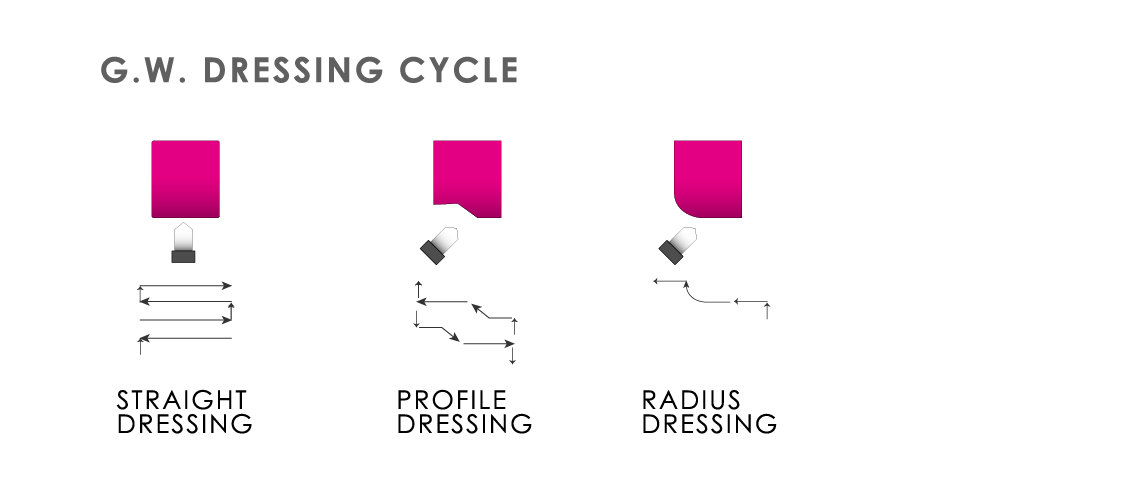

GRINDING CYCLE

.png)

.png)

SPECIFICATION

| Capacity | |

|---|---|

| Swing Over Table | Ø270 mm |

| Distance Between Centers | 400 mm |

| Max. Grinding Diameter | Ø250 mm |

| Max. Grinding Length | 400 mm |

| Max. Load Held Between Centers | 60 kg |

| Center Height (from table to center tip) | 135 mm |

| Grinding Wheel | |

| Size (O.D. x width x I.D.) | Ø405 x 50(max.: 75) x Ø127 mm |

| Linear Velocity | 45 m/sec |

| Worktable | |

| Swiveling Angle | -1° ~ +8° / -1° ~ +5° (dual-drive) |

| Workhead | |

| Swiveling Angle | -30° ~ +90° |

| Center Tapper | MT. No.3 / dual-drive (special center) |

| Spindle Speed | 10 ~ 300 rpm |

| Max. Load of Spindle (tool holder included) | 15 kg (max. length: 100 mm) * Ø155 |

| Tailstock | |

| Center Tapper | MT. No. 3 / dual-drive (special center) |

| Center Moving | Manual (opt.: Automatic) |

| Tailstock Stroke | 25 mm / (opt.: dual-drive 50 mm) / (opt.: hydraulic 30 mm) |

| X-axis Travel | |

| Max. Travel | 300 mm |

| Rapid Feedrate Speed | 10000 mm/Min |

| Auto. Feeding Speed | 0.001 ~ 2000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Z-axis Travel | |

| Max. Travel | 580 mm |

| Rapid Feedrate Speed | 10000 mm/Min |

| Auto. Feeding Speed | 0.001 ~ 2000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Drive Motors | |

| Grinding Wheel Spindle | 5.5 kW |

| Workhead Spindle Motor | 1.0 kW /opt.:0.8 kw (dual-drive)(servo motor) |

| Wheelhead Feed X-axis | 1.5 kW (servo motor) |

| Table Feed X-axis | 1.5 kW (servo motor) |

| Lubrication Oil Pump (Guideway) | NIL |

| Hydraulic Oil Pump( for opt. acc.) | 0.75 kW |

| Coolant Pump | 0.18 kW |

| Tank Capacities | |

| Hydraulic Oil Tank (for opt. acc.) | 18L |

| Lubrication OilTank (Guideway) | P-107 (Auto. Lubrication |

| Coolant Tank | 107 L |

| Machine | |

| Dimension (LxWxH) | 2300 x 2210x1960 mm |

| Net Weight | 4300 kg |

| Center Height (from floor to center tip) | 1100 mm |

* The mentioned specifications & dimensions are subject to change without notice.

ACCESSORIES

STANDARD ACCESSORIES

■

CNC Controller (Brand: SIEMENS 828D) x 1 set

■ Grinding Wheel and Flange x 1 set

■ Carbide Tipped Work Centers (2 pcs/set) x 1 set

■ Diamond Tool Holder ( tailstock mounted type) x 1 set

■ Linear Scale for X-axis x 1 set

■ Grinding Wheel Inverter x 1 set

■ Electric System x 1 set

■ Fully Enclosed Splash Guard x 1 set

■ Lubrication System x 1 set

■ Coolant System x 1 set

■ Work Lamp x 1 set

■ Tools (Leveling pad) and Tool Box x 1 set

■

Air cylinder tailstock

■ Cam-locked Driving Dogs

■ Dual synchronous driving system

■ Work Holder 2 pcs/set

■ 2-point Steady Rest

■ Adjustable 3-point Steady Rest

■ Adjustable 3-jaw Scroll Chuck

■ Adjustable 4-jaw Scroll Chuck

■ Wheel Balancing Stand and Arbor

■ Auto. Grinding Wheel Balancer

■ Spare Grinding Wheel and Flange

■ Jib Crane for Loading / Unloading G.W.

■ Touch Probe Gauge

■ Auto. In-Process Gauge

■ Gap Control

■ Linear Scale for Z-axis

■ Magnetic Coolant Separator

■ Paper Filter

■ Oil Mist Collector