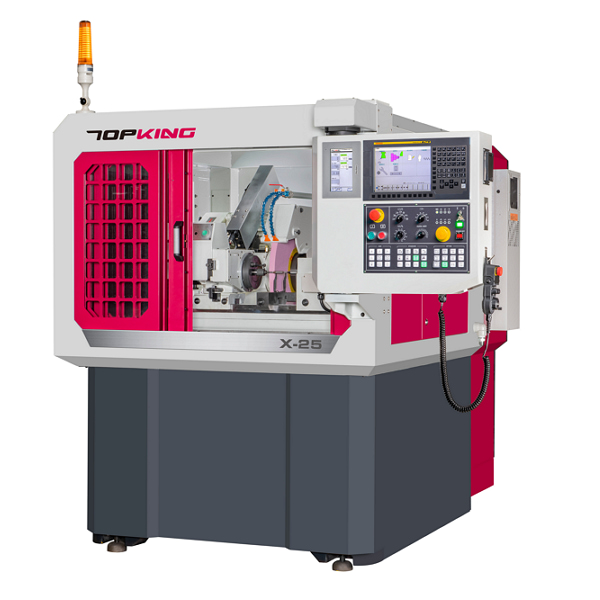

Cylindrical Grinder [cross-slider]

High-Rigidity Cross Slide Structure: Redefining Spatial Standards for CNC Cylindrical Grinders

In the pursuit of ultimate precision in modern manufacturing, TOPKING’s X Series CNC Cylindrical Grinders revolutionize workspace efficiency with a unique Cross Slide design. Unlike traditional grinders with moving tables, the X Series integrates X/Z axes within the slide, keeping the worktable fixed to the base. This "traveling head" configuration reduces floor space requirements by over 30% while significantly enhancing stability and feed speeds during heavy-duty grinding. From the compact X-25 for small-scale precision to the robust X-35100 supporting workpieces up to 200kg, our machines utilize high-grade Meehanite cast iron and hardened box ways to provide a rock-solid foundation, ensuring sub-micron roundness and concentricity for every workpiece.

From Linear Motors to CAM Grinding: Smart Solutions for Aerospace and Hydraulics

To meet the most demanding machining challenges, TOPKING offers a versatile range of advanced technological options. The LM Series features state-of-the-art Linear Motor drives that eliminate backlash—ideal for high-precision components like hydraulic spools and aerospace parts. For non-round geometries, our CAM Series combines C-axis Direct Drive (DD) motors with synchronized control for the flawless grinding of cams, crankshafts, and eccentric shafts. Additionally, angular-head models like the X-2540A or X-3550P allow for simultaneous O.D. and shoulder grinding in a single setup. Equipped with an intuitive Graphical User Interface (GUI) and ready for full automation integration—including in-process gauging and smart collision protection—TOPKING empowers you to achieve high-efficiency, intelligent production in the era of digital manufacturing.