- Home

- BLOG

- Cylindrical Grinder

- NC vs CNC: The Key Role of 2NC Cylindrical Grinders in Between

NC vs CNC: The Key Role of 2NC Cylindrical Grinders in Between

In the journey toward production line automation, selecting the right grinding machine is a critical decision. The 2NC cylindrical grinder offers a solution that balances cost-effectiveness, ease of operation. This article will take a deep dive into the core value of the 2NC cylindrical grinder, exploring everything from its market positioning and technical advantages to its specific differences from CNC grinder.

The Three Core Values of the 2NC Cylindrical Grinder

When it comes to selecting a cylindrical grinding machine, many manufacturers face the same dilemma: Is a traditional NC grinder sufficient, or should we invest directly in CNC grinder?

As the precision machining industry continues to move toward automation and higher accuracy, small and medium-sized factories are often caught between cost, ease of operation, and machining quality. For companies aiming to upgrade their production without overspending, the 2NC cylindrical grinder offers a practical and balanced solution.

Unlike a traditional NC grinder, which can be complex to operate and limited in flexibility, the 2NC grinder design simplifies setup and improves adaptability. At the same time, it avoids the heavy investment and ongoing maintenance costs that typically come with full CNC equipment.

The 2NC cylindrical grinder delivers three core values:

-

Simple operation: New operators can quickly get up to speed, reducing reliance on experienced technicians.

-

Stable precision & higher efficiency: Even during long production runs, the machine maintains consistent dimensions, ensuring low scrap rates and high yields.

-

Flexible investment: Factories can introduce the 2NC cylindrical grinder step by step, with options to integrate measurement systems and automated loading/unloading modules to expand automation capacity.

For manufacturers seeking a balance of productivity, precision, and investment efficiency, the 2NC cylindrical grinder stands out as the golden solution between NC grinders and CNC grinders.

〈Further Reading: GRINDING MACHINE: essential for precision machining in manufacturing industry〉

From Manual to Modern: Smarter Automation, Simplified | 2NC Grinder

Back in the days of experienced craftsmen, the manual cylindrical grinder was a shop floor favorite. The X-axis moved with a handwheel, the Z-axis with hydraulics—no fancy controls, just skill and experience. It was simple, reliable, and affordable, making it perfect for small batches and diverse workpieces.

As factories started moving toward automation, the NC cylindrical grinder filled the gap. With servo control on the X-axis and hydraulic Z-axis, operators could set feed rates and depths, reducing reliance on experience and improving consistency. It was a solid entry point for automation, especially for basic ID and OD grinding works.

But when production demanded higher output and tighter tolerances, problems appeared:

-

The "craftsman's touch" alone couldn't support consistent mass production.

-

NC grinders weren't flexible enough for multi-step processes or strict tolerances.

That's where the 2NC cylindrical grinder shines. It sits between manual, NC, and full CNC grinders, solving these issues while offering a reliable, cost-effective path to automation.

External Cylindrical Grinder Comparison Table

| Item | Manual grinder | NC grinder | 2NC grinder | CNC grinder |

|---|---|---|---|---|

| Structural Features | X-axis feed by handwheel; Z-axis table driven by hydraulics | Z-axis hydraulic drive; X-axis wheelhead driven by servo motor | X and Z axes are driven by servo motors with ball screws。 | Multi-axis servo drive; supports G-code and multi-step programming |

| Operation Mode | Hydraulic drive, no servo or control module | Single-axis NC; feed rate and depth programmable | TOPKING graphic interface; dual-axis NC with built-in protection | CNC system (FANUC/Mitsubishi/Siemens); flexible programming |

| Target Users | Technician-operated; basic ID/OD grinding | Entry-level automation; single-step ID/OD work | SMEs upgrading toward automation | Advanced users; high-volume automated production |

| Cost Level | ★ Lowest | ★★ Low | ★★★ Medium | ★★★★ High |

From the comparison, it's clear that the 2NC cylindrical grinder positions itself as the ideal entry point into automation:

-

Smarter than NC cylindrical grinder: Capable of multi-step grinding, in-process dressing and compensation, and supporting automatic cycles.

-

More affordable than CNC cylindrical grinder: With lower investment cost, easier upkeep, and reduced risk.

In other words, the 2NC cylindrical grinder isn't meant to replace the CNC cylindrical grinder. Instead, it acts as a bridge for manufacturers, addressing today's pain points while providing a low-risk path toward smart manufacturing and future automation upgrades.

T Series 2NC Cylindrical Grinder – Key Highlights

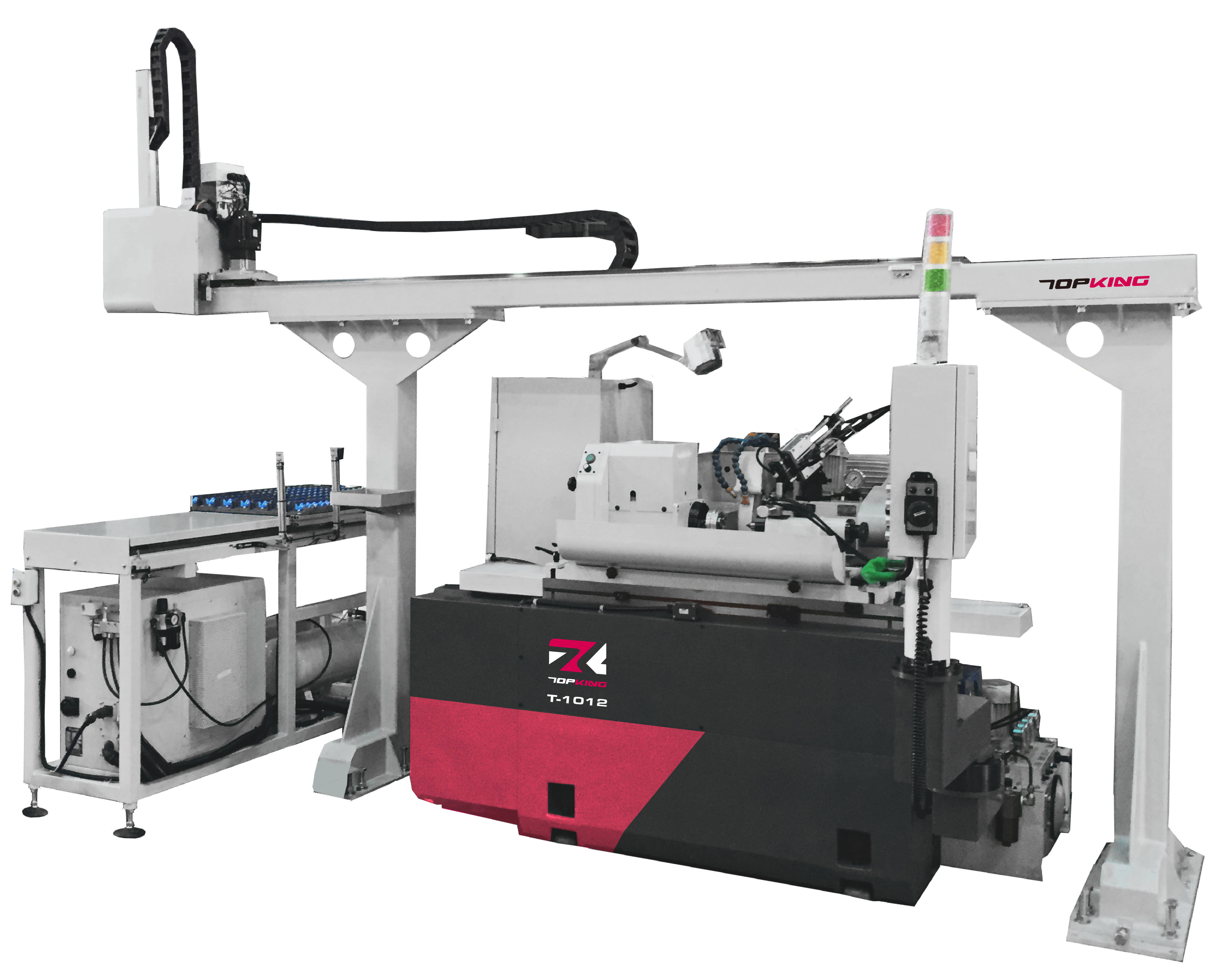

The TOPKING T Series cylindrical grinder is designed as the flagship model for the entry-level automation market. Positioned as an "Easy CNC" solution, it features servo-driven X and Z axes, combining high precision with user-friendly operation. This makes it an ideal choice for small and medium-sized manufacturers taking their first step toward automation.

2NC Operating System

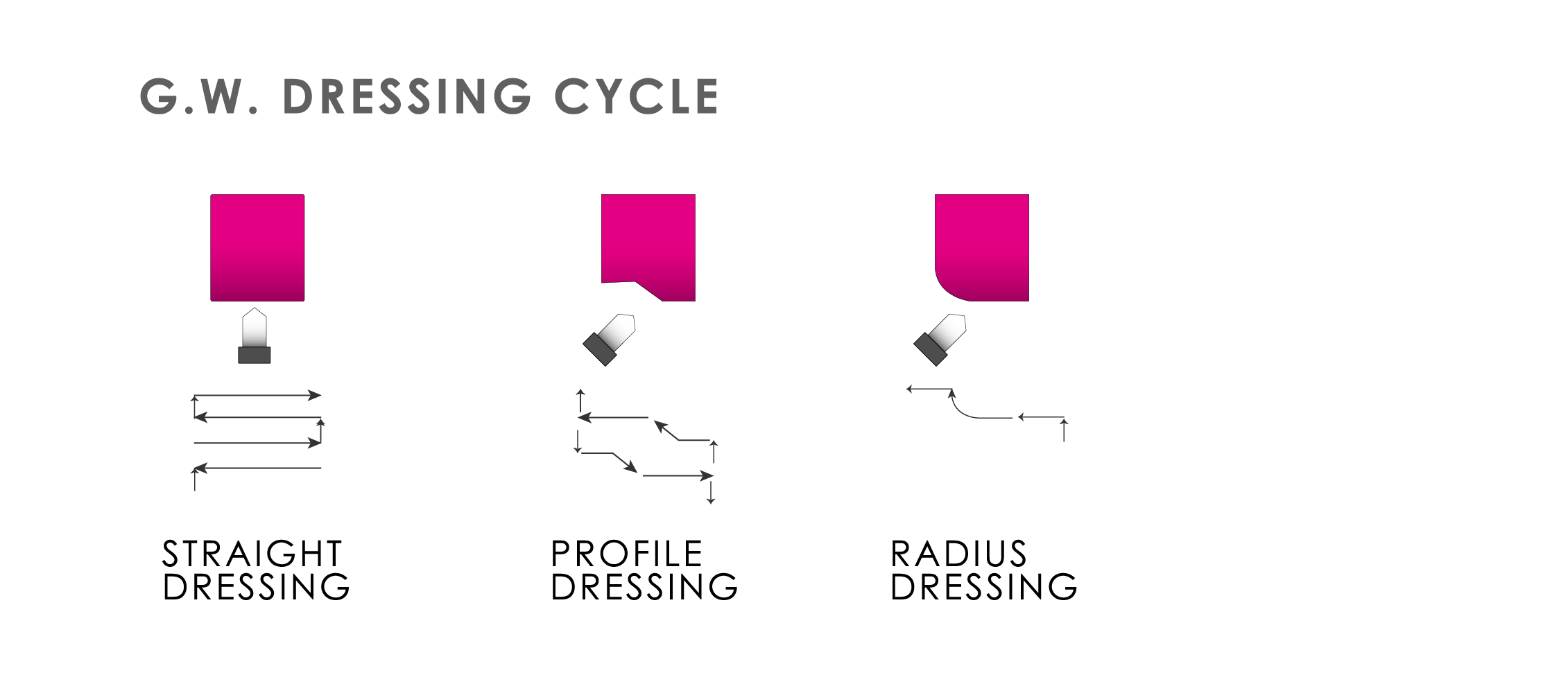

The 2NC cylindrical grinder is built around simplicity and efficiency. With one-touch memory and automated grinding cycles, it minimizes setup time and ensures consistent results across production.2. One-Touch Memory: Quickly stores machine zero points, grinding positions, and dressing coordinates, minimizing repetitive setup and human error.

3. Automatic Cycle: Supports one-touch multi-step grinding and wheel dressing for stable, consistent production.

4. Built-in Safety Protection: Reduces crash risks, allowing even new operators to work with confidence.

%20(1)(1).jpg)

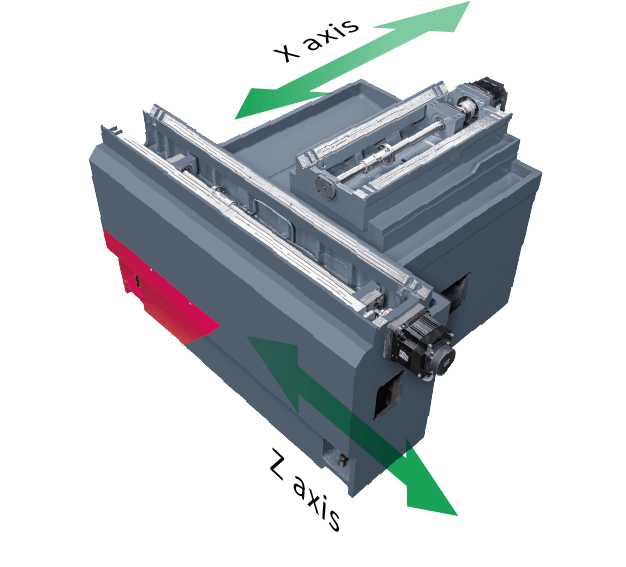

Machine Structure

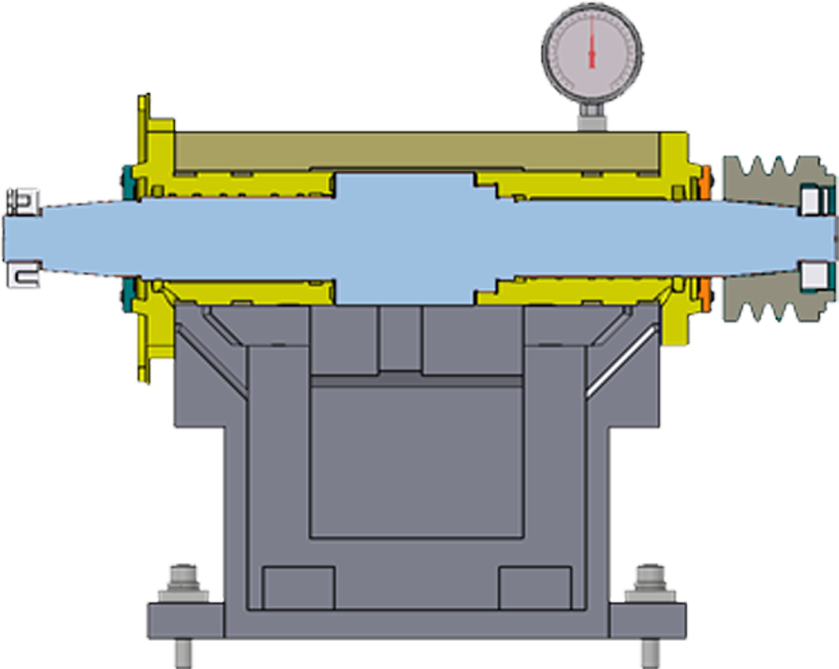

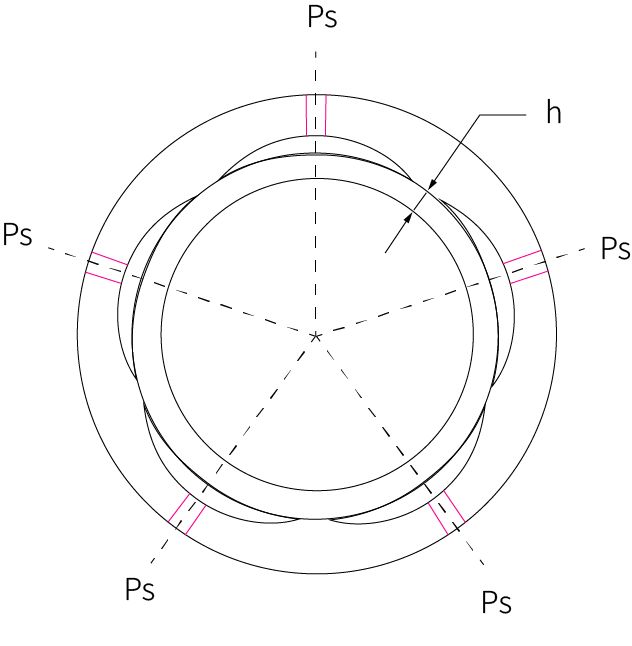

1. 1V1 Flat + Hydrostatic Lubrication System — Ensures smooth feed motion and higher machining accuracy.

2. Rigid, Non-Lightweight Design — Prevents deformation; maintains stable precision even under long-term continuous operation for consistent production quality.

.png)

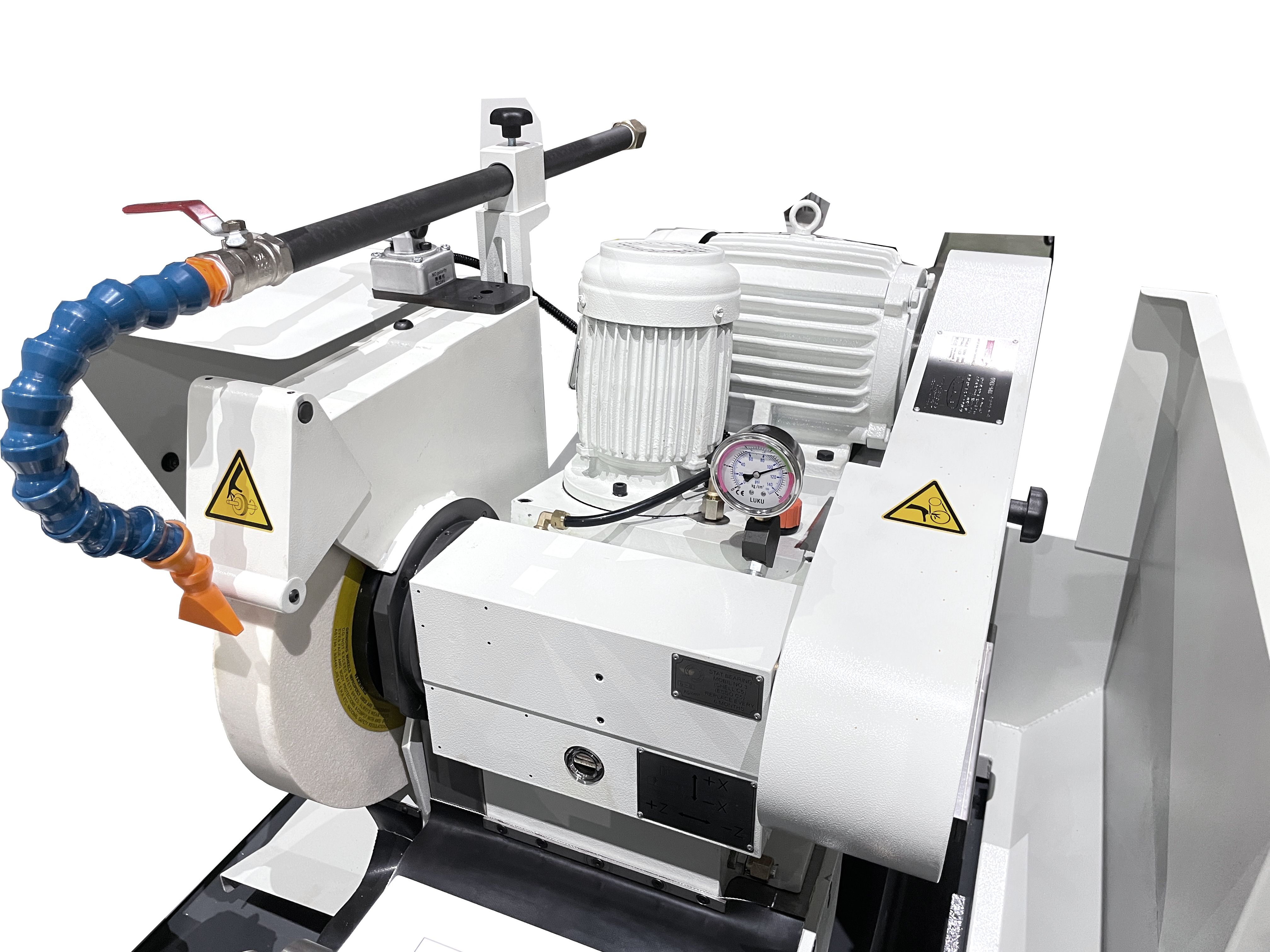

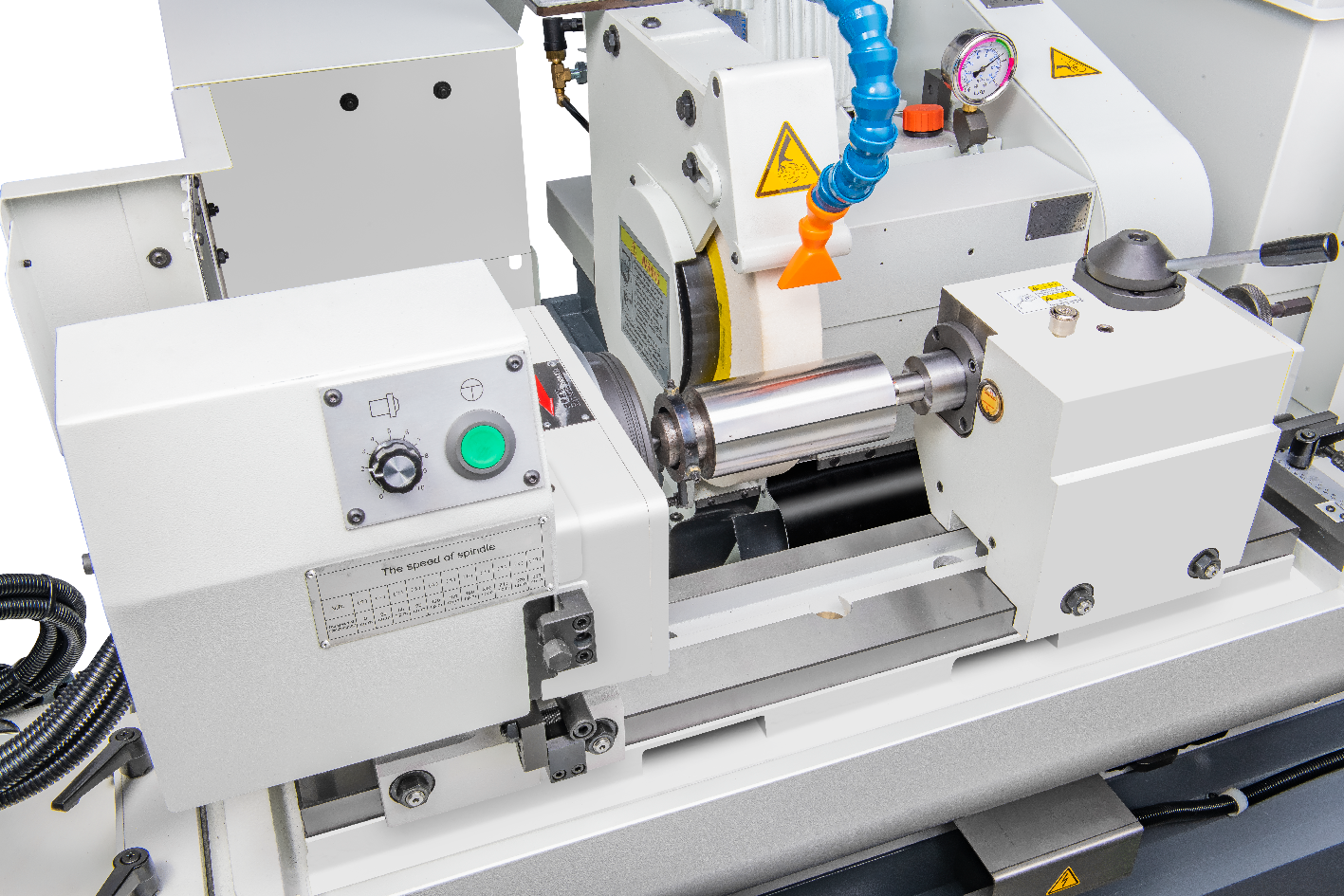

Grinding Spindle

1. Premium SNCM-220 Alloy Steel — Carburized, cryogenically treated, and mirror-finished. Surface hardness exceeds HRC62° delivering exceptional durability and long service life.

2. Hydrostatic Spindle — Supported by an oil film with zero contact, ensuring near-zero wear, excellent vibration damping, and minimal thermal deformation—ideal for long, stable production runs.

Workhead & Tailstock

1. Workhead:

- Equipped with precision-grade bearings for maximum stability.

- Servo-driven with stepless variable speed adjustment.

- Adjustable angle design for tapered workpiece grinding.

2. Tailstock: Oil-bath lubrication with oil-level indicator ensures stable accuracy and long-term durability.

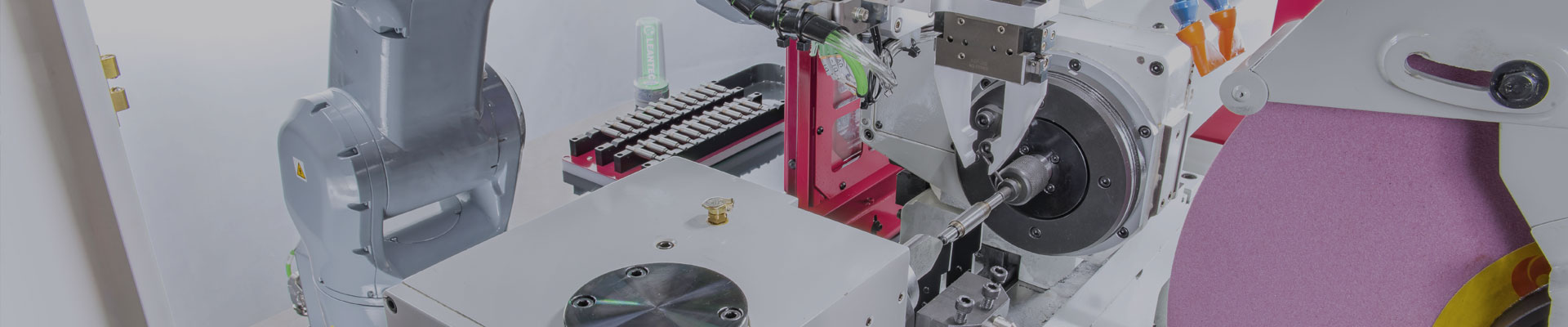

Flexible Automation Upgrades

The 2NC cylindrical grinder can be used as a standalone machine or seamlessly expanded with measuring systems, automatic loading/unloading modules, or full production line integration — significantly enhancing productivity and manufacturing flexibility.

Typical Workpiece Applications

Compared to traditional NC grinders, the TOPKING T Series 2NC cylindrical grinder combines easy operation with high-precision grinding. It handles a wide variety of workpieces while maintaining stable and consistent accuracy—even during long production runs.

Best-Suited Workpieces

-

Short shafts: Efficient plunge grinding

-

Long shafts: Multi-section traverse grinding with high efficiency

-

Stepped diameters: Automatic multi-step cycle machining

-

Tapered parts: Adjustable workhead angle for taper grinding

-

Sleeves & hydraulic parts: Excellent long-term stability

The T Series 2NC cylindrical grinder is widely used across automotive, hydraulic, pneumatic, and machine tool component industries, making it an ideal solution for high-volume precision part production.

Industry Applications

-

Automotive components: drive shafts, crankshafts, bushings

-

Hydraulic & pneumatic parts: cylinder sleeves, valve components

-

Machine tool components: spindles, sleeves

Why Choose the T Series? – The 5 Most Frequently Asked Questions

When selecting or using the T Series 2NC cylindrical grinder, customers often raise similar technical questions. Here are the top five FAQs with clear answers:

1. Is the T Series difficult to operate?

Not at all. The graphical user interface (GUI) eliminates complex coding—operators simply input values. The learning curve is minimal, even for beginners.

2. How long can it maintain precision?

Thanks to the hydrostatic spindle and high-rigidity structure, the T Series consistently maintains accuracy within ±0.005mm during long production runs.

3. What's the difference compared to CNC?

CNC grinders offer the highest flexibility and are ideal for complex forms. The 2NC grinder, however, is more cost-effective and practical for OD and step grinding where simplicity and efficiency matter most.

4. What types of workpieces is it best suited for?

Short shafts, stepped diameters, tapered parts, sleeves, and hydraulic components.

5. What's the typical ROI (Return on Investment)?

Most customers report an ROI within 1–2 years, depending on production volume and automation setup.

These questions cover the key factors manufacturers care about most: ease of operation, precision stability, machine comparison, workpiece suitability, and investment benefits. Together, they highlight why the T-Series 2NC cylindrical grinder is the smart choice for manufacturers entering automation.

〈Featured Products:Cylindrical Grinder 2NC | T series〉

What's the Difference Between 2NC and CNC Grinding?

When choosing a cylindrical grinder, differences in grinding method and operation logic are often the key factors. The T-Series2NC cylindrical grinder and a CNC cylindrical grinder each offer unique advantages depending on production needs.

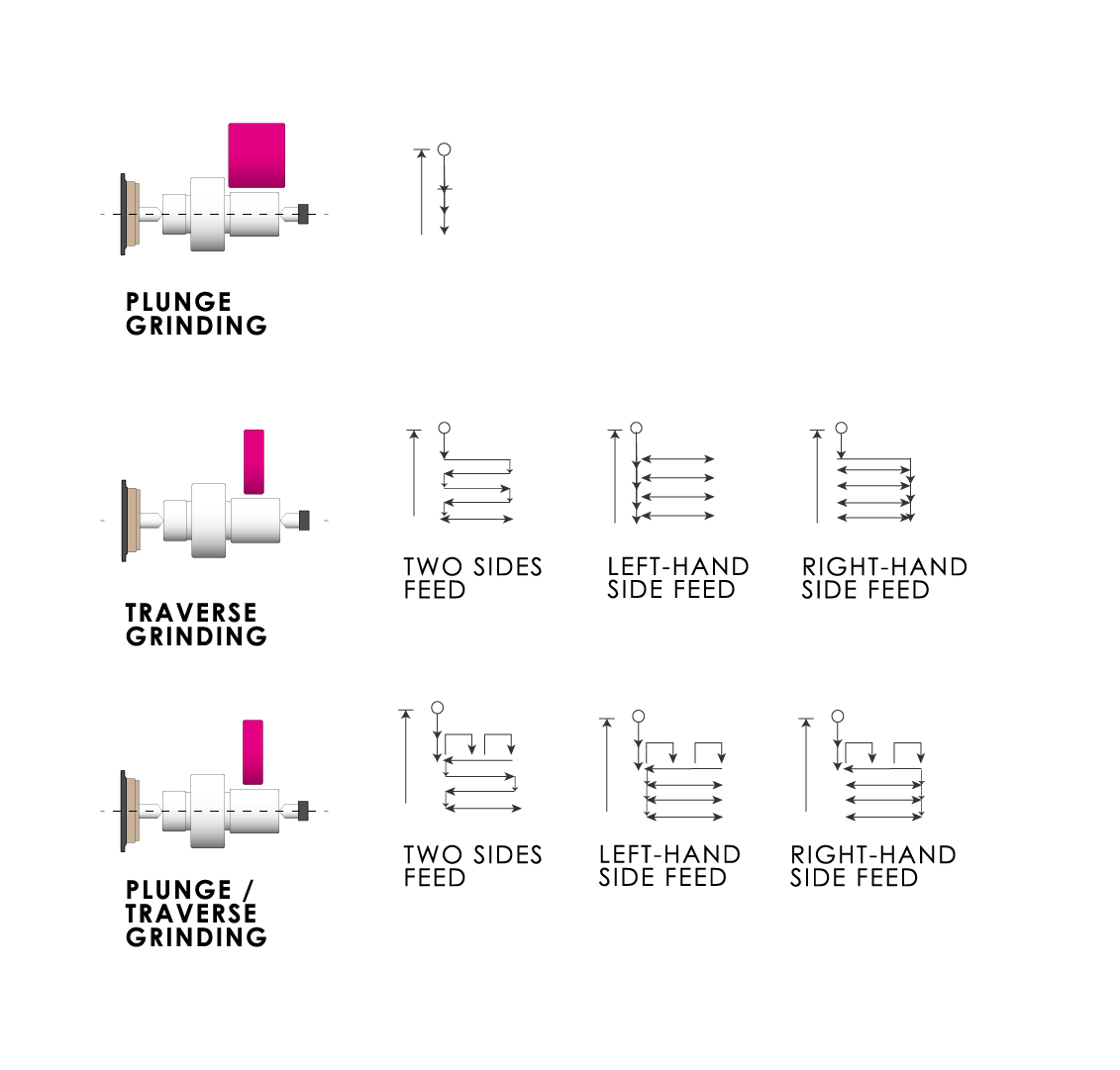

1. 2NC Cylindrical Grinding

-

Operation Logic: Value-based input with no programming required. Grinding tasks are managed through an intuitive graphical user interface (GUI).

-

Grinding Range: Handles diameters, traverse grinding, step grinding, and tapers—ideal for multi-step plunge operations.

-

Processing Features: Supports automatic cycles and multi-stage grinding, ensuring efficiency and consistent quality.

-

Limitations: Does not support complex curves or freeform contour grinding.

-

Best Suited For: High-volume, repetitive parts with simple geometries.

01.png)

01.png)

03.png)

2. CNC Cylindrical Grinding

-

Operation Logic: Programmed via CNC systems (FANUC, Mitsubishi, Siemens) using G-code.

-

Grinding Range: Capable of straight, curved, grooved, and special contour grinding.

-

Processing Features: Extremely flexible; handles complex shapes and precision requirements with ease.

-

Limitations: Requires programming skills, with higher operating and maintenance costs, plus a larger investment.

-

Best Suited For: Diverse, low-volume, or highly complex workpieces.

.png)

| Item | 2NC Cylindrical Grinder | CNC Cylindrical Grinder |

|---|---|---|

| Operation | Graphical interface, no programming needed, simple value input | G-code programming, highly flexible |

| Grinding Range | OD, steps, tapers | OD, steps, tapers, curves, profile grinding |

| Profile Grinding Capability | ✘ Not supported | ✔ Supports complex profile grinding |

| Investment Cost | ★★ Medium, easy to maintain | ★★★ Higher, with greater maintenance cost |

| Best Suited For | High-repeat, large-volume, standard parts | Diverse, low-volume, complex parts |

For common workpieces such as diameters, traverses, steps, and tapers, the 2NC cylindrical grinder delivers stable precision and high efficiency, striking the ideal balance between operational flexibility and cost-effectiveness. For parts with more complex shapes, or those requiring profile grinding and special contour machining, a high-end CNC cylindrical grinder remains the preferred solution.

Conclusion

The T Series 2NC cylindrical grinder occupies a golden market position as a bridge between traditional NC and full CNC machines for small and medium-sized manufacturers. It addresses challenges such as high operation complexity, limited batch processing efficiency, and high initial automation investment. At the same time, the T Series supports phased upgrades, allowing integration with measuring systems or automatic loading/unloading modules to make production lines flexible for future needs. Overall, it represents a practical, reliable precision grinding solution, making it an ideal first step toward automation. If you are interested in our 2NC cylindrical grinder, we invite you to download our product catalog or contact us directly. Our team is dedicated to providing you with professional purchasing advice and full technical support.

〈Further Reading:How to Choose the Right CNC Grinder: Match the Control System and Machine to Your Production Needs〉

Article Classification

Recent Articles

- NC vs CNC: The Key Role of 2NC Cylindrical Grinders in Between

- How to Choose the Right CNC Grinder: Match the Control System and Machine to Your Production Needs

- Hydrostatic Technology: The Key to Stable Centerless Grinding

- Automated Match Grinding Solutions for Hydraulic Valve Components

- Struggling with Inefficient Grinding Operations?