CNC CAM grinding

X-2540CAM

CNC CAM grindingINTRODUCTION

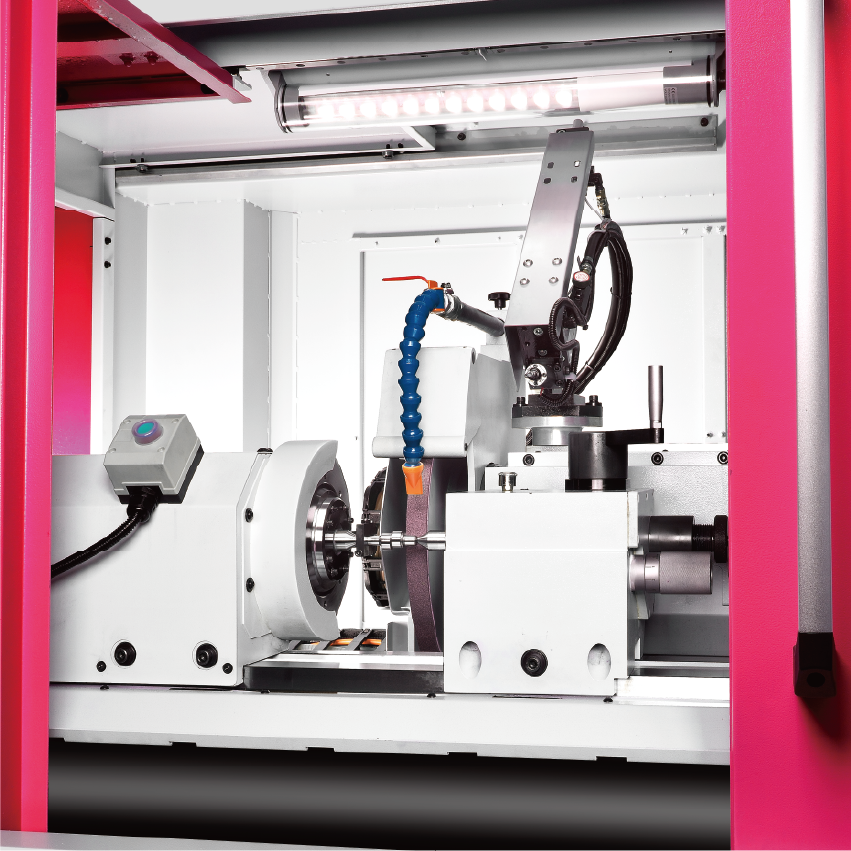

The TOPKING X-2540CAM is a CNC non-round grinding machine designed for CAM-controlled contour grinding under space-constrained conditions. The machine adopts a cross-slide structure combined with linear motor drives and direct drive systems, enabling zero mechanical backlash and high dynamic response during non-circular interpolation.

Precise C-X axis synchronization supports stable contour generation for non-round profiles. The machine is suitable for grinding polygon punches, small camshafts, eccentric pins, and precision medical components, where consistent μm-level accuracy and repeatability are required.

| CAPACITY

Swivel Over Table: Ø270 mm

Distance Between Center: 400 mm

Max. Grinding Dia.: Ø250 mm

Max. Grinding Length: 400 mm

MACHINE FEATURE

USER FRIENDLY OPERATION SYSTEM

■ Equipped with SIEMENS SINUMERIK ONE control system. Built-in TOPKING’s latest version graph conversational operate interface includes crankshaft and camshaft grinding application. Make work easier! Moreover, operating with CAD/CAM software (optional accessories) easy to programming the custom-made grinding graphics. Provide a flexible and humanized operating environment.

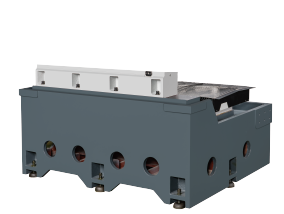

RIGID MACHINE BASE

■ High rigidity machine base made of Meehanite cast iron through annealing and aging treatment.

■ Slideway though high-frequency hardening and precision grinding process. Machine base with stable material and strengthen construction for deformation-free and outstanding wear resistance.

WORK TABLE

■ The work table is permanently bolted to the machine. The cross-slide design is adopted to reduce travel. It can improve working speed and precision stability.

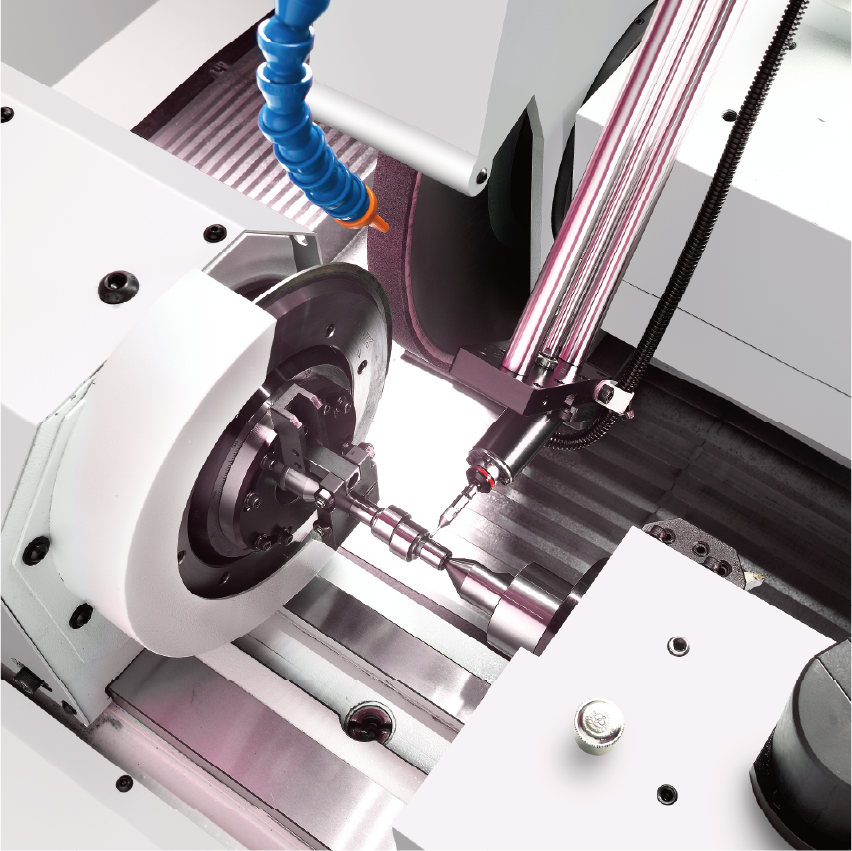

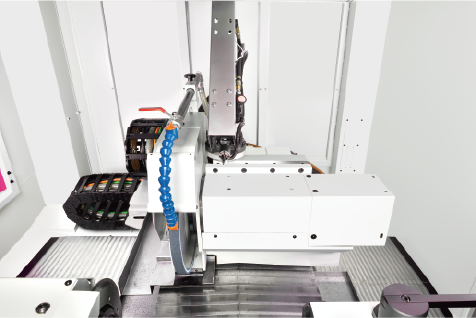

CROSS-SLIDER DESIGN & AXIS GUIDANCE

■ X and axes are designed as cross-sliders to reduce machine space.■The X-axis is driven directly by a linear motor, combined with linear guides, to achieve smooth axial movement. Equipped with a high-resolution linear scale as standard, ensuring stable repeatability precision and guaranteeing utmost precision during the machining process.

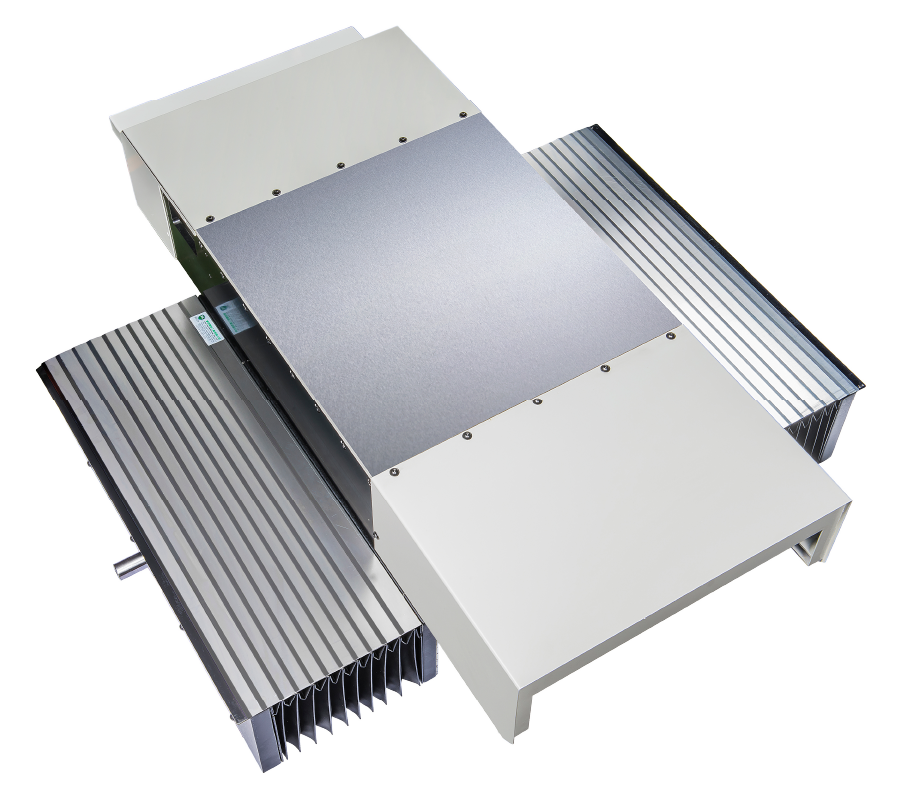

■ Two axes covered by enclosed telescopic covers. To protect the transmission structure and prevent contamination from grinding debris and coolant.

X-AXIS DRIVEN BY LINEAR MOTOR

■ X axis is driven by a linear motor directly, with no backlash for achieving more precise position control.

■ Cross-slider construction with high-speed precision linear motor and closed-loop control linear scale on X axis. Apply the smoothest working condition with the C axis.

■ Moving speed could reach 15000 mm/Min.

■ Linear motors constitute of coil and permanent magnets. No attrition for longer uses life and contributes to energy savings and increased efficiency.

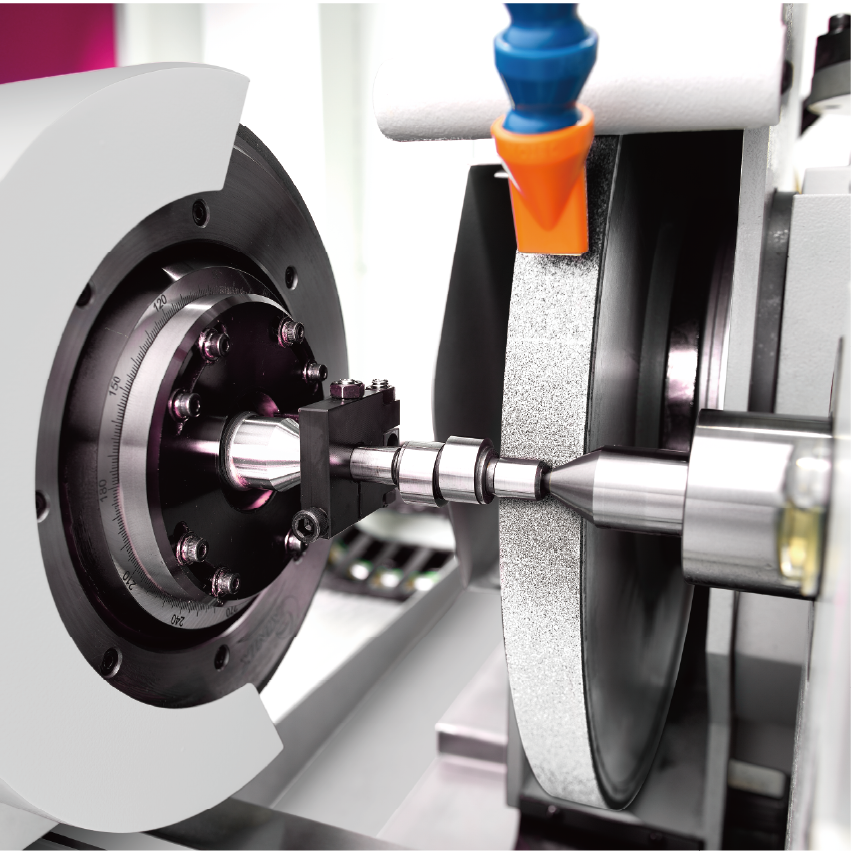

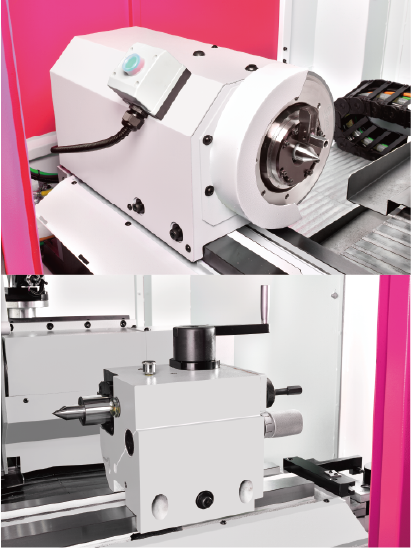

WHEELHEAD CONSTRUCTION

Built-in spindle for grinding wheel.

■ The lightweight design of the wheelhead seat mitigates resonances stemming from conventional transmission components, thereby stabilizing the grinding process and elevating machining precision.

■ Built-in spindle proficiently manages and monitors spindle temperatures, effectively safeguarding against thermal deformation issues.

■ Built-in spindle's high-speed rotation and rapid response to acceleration and deceleration enable the fulfillment of speed adjustments and consistency required for intricate contour grinding.

■ Built-in spindle offers lower energy consumption and reduced pollution emissions, achieving benefits in energy efficiency and environmental conservation.

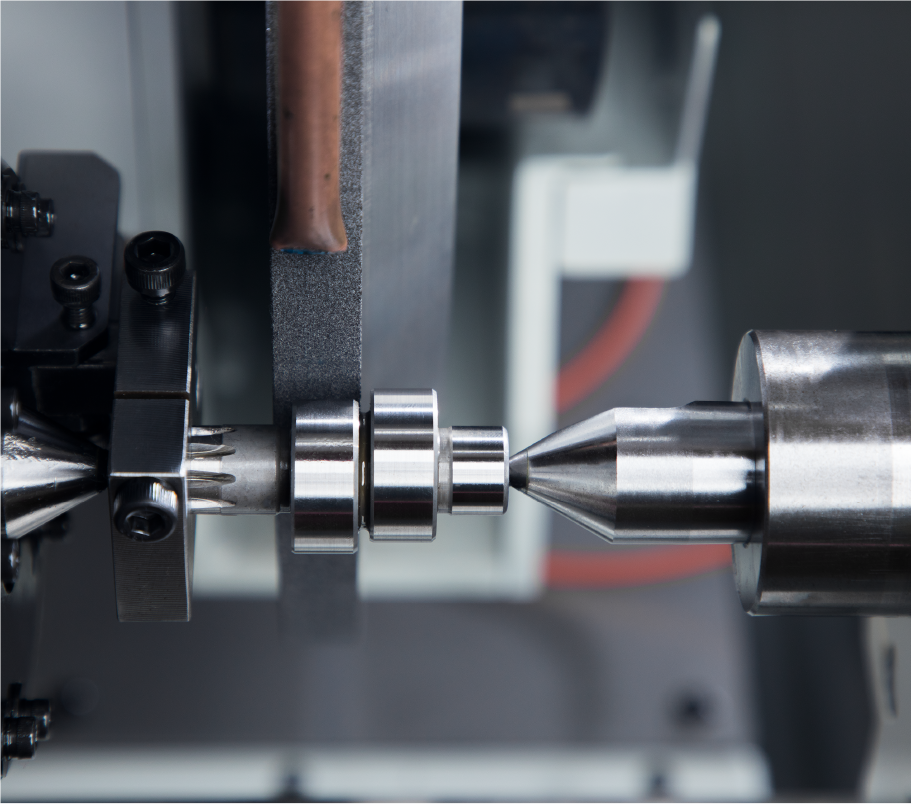

WORKHEAD SPINDLE

■ Working spindle equipped with a Direct Drive motor and precision angle encoder. High resolution of angle tolerance control ±0.2”. Accurate angle control applies for various eccentric, cam shaft, crank shaft, and polygon punch grinding.

■ Could do micro-adjustment for taper correction.

FINE ADJUSTMENT TAILSTOCK

■ An auto. oil bath lubrication system has been provided for tailstock to maintain high-level accuracy.

■ The oil level gauge provides a quick check of the oil level.

■ Could adjust enables taper correction in centers fixed grinding way.

SPECIFICATION

| Capacity | |

|---|---|

| Swing Over Table | Ø270 mm |

| Distance Between Centers | 400 mm |

| Max. Grinding Diameter | Ø250 mm |

| Max. Grinding Length | 400 mm |

| Max. Load Held Between Centers | 15 kg |

| Center Height (from table to center tip) | 135 mm |

| Grinding Wheel | |

| Size (O.D. x width x I.D.) | Ø405 x 50 x Ø127 mm |

| Linear Velocity | 45 m/sec |

| Worktable | |

| Swiveling Angle | -1°~ +8° |

| Workhead | |

| Swiveling Angle | Fixed Type |

| Center Tapper | MT. No. 3 |

| Spindle Speed | 10 ~ 300 rpm |

| Max. Load of Spindle (tool holder included) | 5 kgs (max. length: 100 mm) |

| Tailstock | |

| Center Tapper | MT. No. 3 |

| Center Moving | Manual type |

| Tailstock Stroke | 25 mm |

| Barrel Stroke | ±30 μm |

| Cylindricity with Micro Adjustment | ±0.03 mm |

| X-axis Travel | |

| Max. Travel | 300 mm |

| Rapid Feedrate Speed | 20000 mm/Min |

| Auto. Feeding Speed | 6000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Z-axis Travel | |

| Max. Travel | 580 mm |

| Rapid Feedrate Speed | 10000 mm/Min |

| Auto. Feeding Speed | 6000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Drive Motors | |

| Grinding Wheel Spindle | 11.4 kW (built-in motor) |

| Workhead Spindle | 22.3 Nm (direct drive motor) |

| Wheelhead Feed X-axis | 1750 N (linear motor) |

| Table Feed Z-axis (servo motor) | 2.29 kW (servo motor) |

| Lubrication Oil Pump | NIL |

| Hydraulic Oil Pump | 0.37 kW |

| Coolant Pump | 0.37 kW |

| Tank Capacities | |

| Lubrication Oil Tank 1 | 18 L |

| Lubrication Oil Tank 2 | P-107 |

| Hydraulic Oil Tank | 18 L |

| Coolant Tank | 107 L |

| Machine | |

| Dimension | 2300 x 2210 x 1960 mm |

| Machine Weight | 4300 kg |

| Center Height (from floor to center tip) | 1110 mm |

* The mentioned specifications & dimensions are subject to change without notice.

ACCESSORIES

STANDARD ACCESSORIES

■ CNC Controller (Brand: SIEMENS SINUMERIK ONE) x 1set

■ Grinding Wheel and Flange x 1 set

■ Grinding Wheel Inverter x 1 set

■ Diamond Tool Holder (workhead spindle mounted type) x 1 set

■

Cooler system for work-spindle servo x 1 set

■ Carbide Tipped Work Centers (2 pcs/set) x 1 set

■ Micro Adjustment Tailstock x 1 set

■ Linear Motor for X-axis x 1 set

■ Linear Scale for X-axis x 1 set

■ Rotary Scale for C-axis x 1 set

■ CAD-CAM Software Graphical Programming x 1 set

■ Electric System x 1 set

■ Fully Enclosed Splash Guard x 1 set

■

Lubrication System x 1 set

■ Coolant System x 1 set

■ Oil Mist Collector x 1 set

■ Work Lamp x 1 set

■ Tools (Leveling pad) and Tool Box x 1 set

■ Cam-locked Driving Dogs

■ Work Holder (2pcs/set)

■ 2-point Steady Rest

■ Adjustable 3-jaw Scroll Chuck

■ Adjustable 4-jaw Scroll Chuck

■ Diamond roller dressing device (connecting with workhead by flange)

■ Diamond roller dressing device (tailstoke mounted type)

■ Air Cylinder Tailstock

■ Wheel Balancing Stand and Arbor

■ Auto. Grinding Wheel Balancer

■ Spare Grinding and Wheel Flange

■ Touch Probe Gauge

■ Gap Control

■ Jib Crane for Loading / Unloading G.W.

■ Customized Workpiece Drive Fixture

■ Magnetic Coolant Separator

■ Paper Filter