2NC series | T series

T -1020

CYLINDRICAL GRINDERINTRODUCTION

As a high-value entry-level CNC model, the T-1020 offers an impressive working range: a maximum swing over table of Ø270 mm and a distance between centers of 500 mm. Designed specifically for small-to-medium multi-step shaft components, it handles grinding diameters up to Ø250 mm with ease. It is the perfect choice for manufacturers seeking to balance procurement budget with superior machining flexibility.

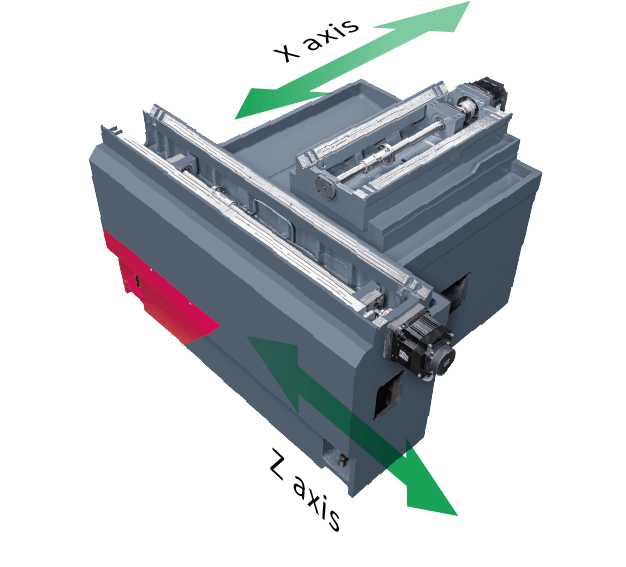

Both X and Z axes are driven by servo motors and equipped with an intuitive Graphical User Interface (GUI). This conversational system transforms complex programming into straightforward numerical settings, allowing operators to master the machine quickly without any prior programming experience. Combined with a high-rigidity structure and a hydrostatic automatic lubrication system, the T-1020 ensures stable feeding and delivers consistent, micron-level precision.

| CAPACITY

Swivel Over Table: Ø270 mm

Distance Between Center: 500 mm

Max. Grinding Dia.: Ø250 mm

Grinding Wheel: Ø355 x 50 x Ø127 mm

MACHINE FEATURE

HIGH PERFORMANCE GRAPHICAL USER INTERFACE

■ TOPKING's latest graphic dialogue operation interface provides the operator with the most convenient, simplest and safest operating environment.

■ Different from the previous program editing, the numerical programming setting can automatically execute the grinding cycle, dressing cycle, correction and other commands.

■ It can memorize the coordinates of mechanical origin, grinding, dressing, compensation with one key.

■ Various grinding and dressing methods can be selected according to the needs of the work.

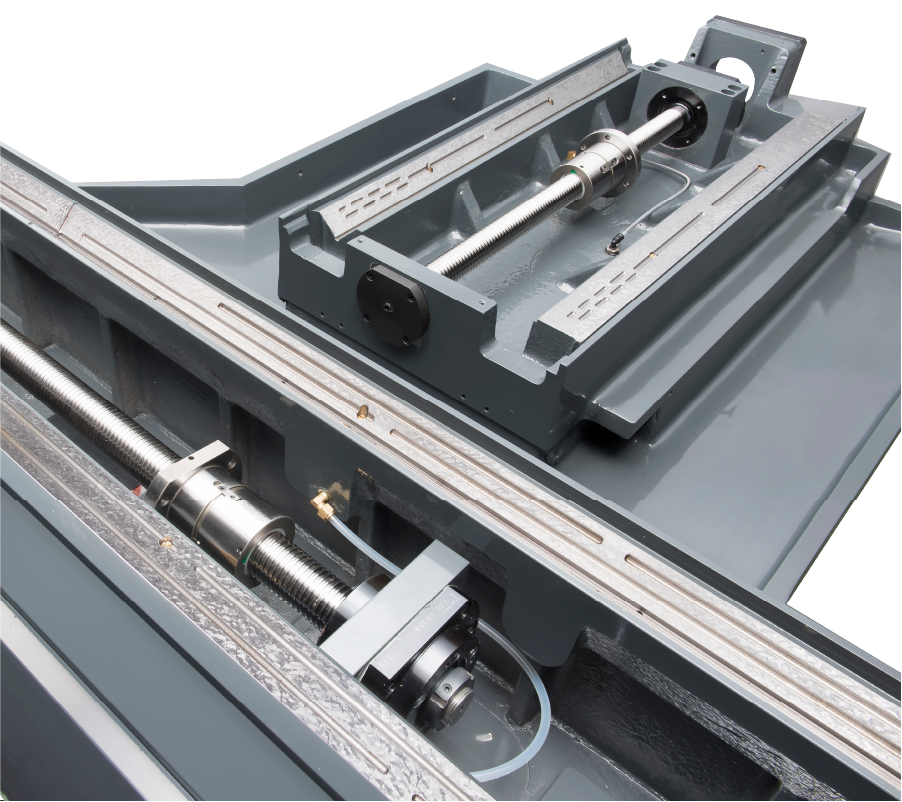

RIGID MACHINE BASE

■ The structure of the machine is different from the previous lightweight design concept; it greatly strengthens the structural rigidity of the machine body and parts. In pursuit of more stability, it adopts a thicker and stronger sliding seat mechanism, the slideway 1V 1 flat structure, and a lubrication system designed by the principle of static pressure, providing the best precision and stability when grinding.

HYDROSTATIC LUBRICATION SYSTEM

■ The slideways of the table and the wheel head are lubricated by an advanced automatic hydrostatical lubrication system.■ The lubrication performance of the worktable and the wheelhead has been significantly enhanced, showcasing exceptional grinding smoothness. Moreover, with the optimized operational fluidity, it becomes possible to achieve higher precision in the feed rate, ensuring the accuracy of the machining process.

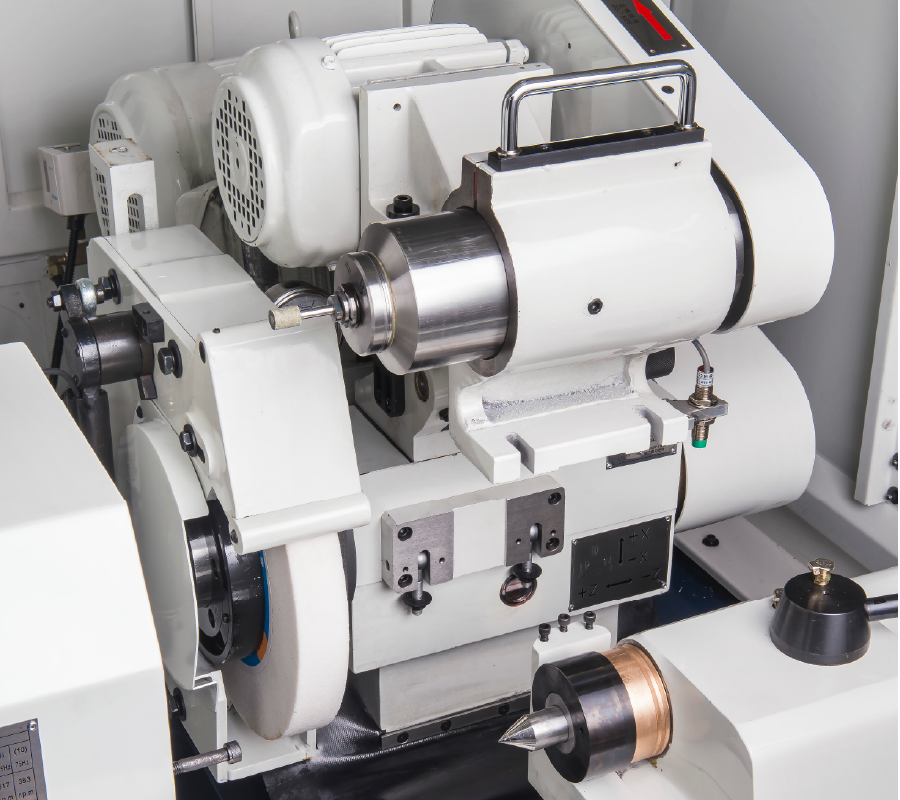

WHEELHEAD CONSTRUCTION

■ The G.W. spindle is made of high-quality alloy steel SNCM-220, which has undergone multiple treatments such as normalization, quenching and tempering, carburizing heat treatment, and cryogenic treatment. Afterwards, precision grinding and mirror treatment are carried out, and the surface hardness reaches above HRC62°. Guarantee no deformation, wear resistance, high precision forever.

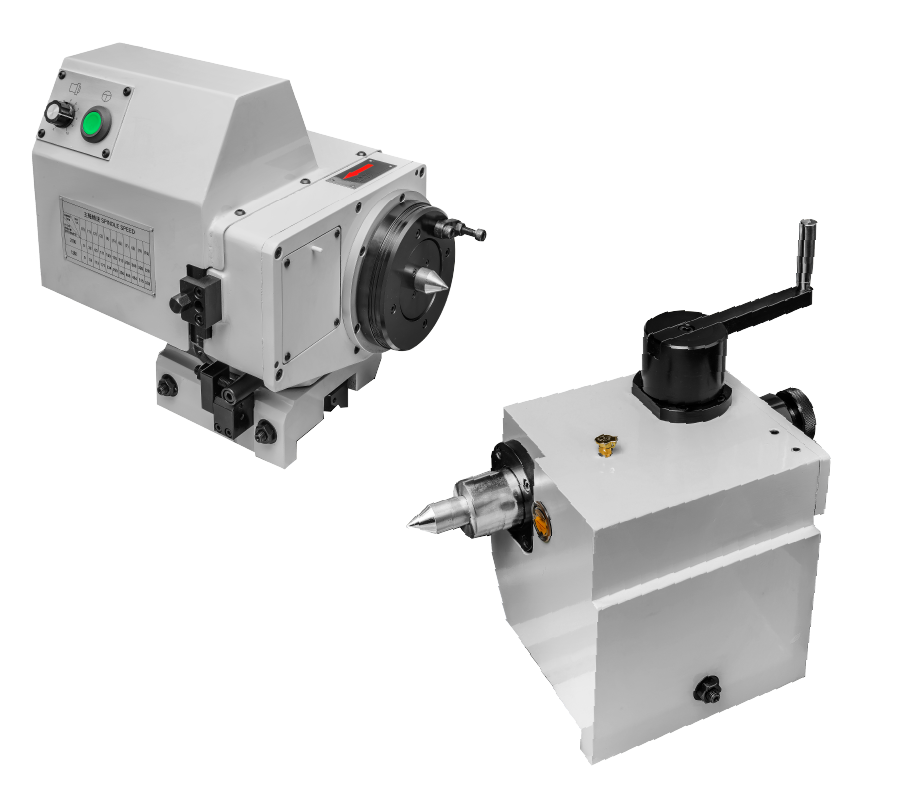

WORKHEAD AND TAILSTOCK

■ The work spindle utilizes precision-grade bearings, showcasing optimal stability.

■ The workhead is driven by a servo motor, enabling continuous and infinitely variable speed adjustments based on demand.

■The workhead features a fixed-type work spindle, enhancing accuracy and stability.

■ The tailstock lubrication adopts an oil-bath lubrication system, ensuring consistent high precision of the tailstock at all times.

■ The lubrication system is equipped with an oil gauge for convenient monitoring of oil quantity by operators.

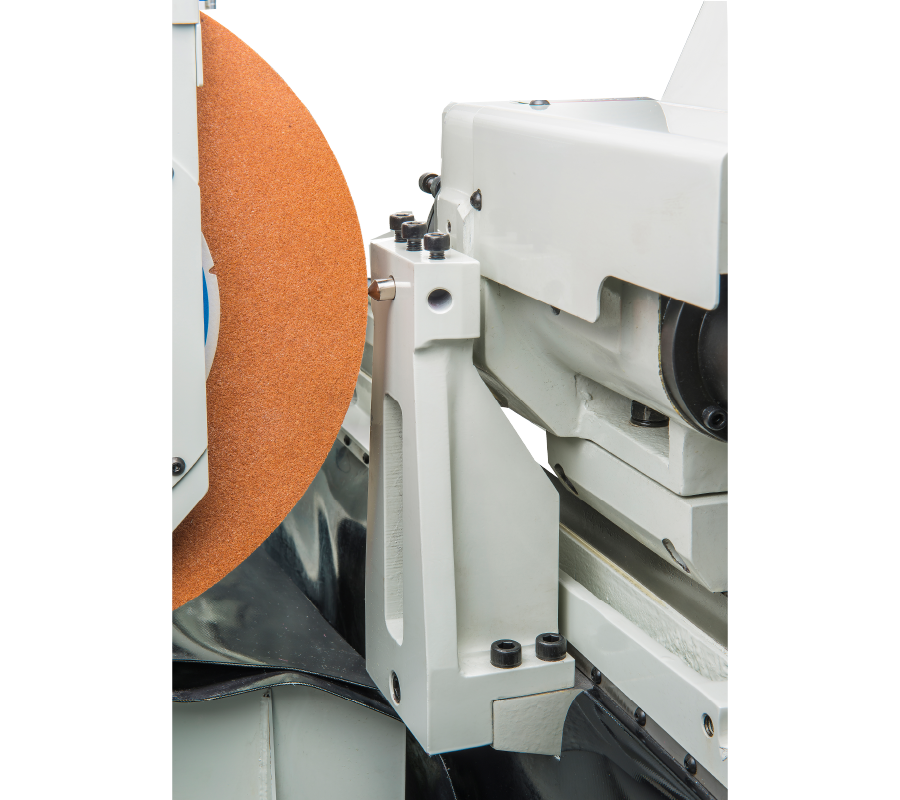

DIAMOND TOOL HOLDER

(slider mounted type)

■ The dressing device is affixed to the Z-axis slide, minimizing errors caused by repeated dressing position calibrations due to adjustments in the worktable angle.

■ Diverse dressing device is available, adaptable to the requirements of the component.

SPECIFICATION

| Capacity | |

|---|---|

| Swing Over Table | Ø270 mm |

| Distance Between Centers | 500 mm |

| Max. Grinding Diameter | Ø250 mm |

| Max. Grinding Length | 500 mm |

| Max. Load Held Between Centers | 60 kg |

| Center Height (from table to center tip) | 135 mm |

| Grinding Wheel | |

| Size (O.D. x width x I.D.) | Ø355 x 38~50 x Ø127 mm |

| Linear Velocity | 33 m/sec |

| Worktable | |

| Swiveling Angle | 0° ~ +12° |

| Workhead | |

| Swiveling Angle | -30° ~ +90° |

| Center Tapper | MT. No. 3 (opt.: MT. No. 4) |

| Spindle Speed | 10 ~ 300 rpm |

| Max. Load of Spindle (tool holder included) | 15 kgs (Max. Length: 150 mm) |

| Tailstock | |

| Center Tapper | MT. No. 3 (opt.: MT. No. 4) |

| Center Moving | Manual type |

| Tailstock Stroke | 25 mm |

| X-axis Travel | |

| Max. Travel | 220 mm |

| Rapid Feedrate Speed | 6000 mm/Min |

| Auto. Feeding Speed | 0.001 ~ 2000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Z-axis Travel | |

| Max. Travel | 760 mm |

| Rapid Feedrate Speed | 6000 mm/Min |

| Auto. Feeding Speed | 0.001 ~ 2000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Drive Motors | |

| Grinding Wheel Spindle | 3.75 kW |

| Workhead Spindle Motor | 0.85 kW (AC servo motor) |

| Wheelhead Feed X-axis | 1.0 kW (AC servo motor) |

| Table Feed X-axis | 1.5 kW (AC servo motor) |

| Lubricantion Oil Pump | 0.075 kW |

| Wheel Spindle Lubrication Oil Pump | 0.18 kW |

| Coolant Pump | 0.18 kW |

| Tank Capacities | |

| Wheel Spindle Lubrication Oil Tank | 14 L |

| Lubrication Oil Tank | 15 L |

| Machine | |

| Dimension (L x W x H) | 2770 x 1630 x 2112 mm |

| Net Weight | 3000 kg |

| Center Height (from floor to center tip) | 1057 mm |

* The mentioned specifications & dimensions are subject to change without notice.

ACCESSORIES

STANDARD ACCESSORIES

■ Grinding Wheel and Flange x 1 set

■ Carbide Tipped Work Centers (2 pcs/set) x 1 set

■ Diamond Tool Holder (slider mounted type) x 1 set

■ Electric System x 1 set

■

Lubrication System x 1 set

■ Coolant System x 1 set

■ Work Lamp x 1 set

■ Tools (Leveling pad) and Tool Box x 1 set

■ Internal Grinding Attachment (incl. one spindle and G.W. inverter)

■ Hydraulic Tailstock

■ Cam-locked Type Driving Dog

■ Work Holders 2 pcs/set

■ 2-Point Steady Rest

■ 3-Point Steady Rest

■ 3-jaw Chuck

■ 4-jaw Chuck

■ Spare Grinding Wheel and Flange

■ Diamond Roller Dressing Device (connecting with workhead by flange)

■ Wheel Balancing Stand & Arbor

■ Automatic Grinding Wheel Balancer

■ Touch Probe Gauge

■ Auto. In-Process Gauge

■ Semi-Splash Guard

■ Fully Enclosed Splash Guard

■ Magnetic Coolant Separator

■ Paper Filter

■ Oil Mist Collector