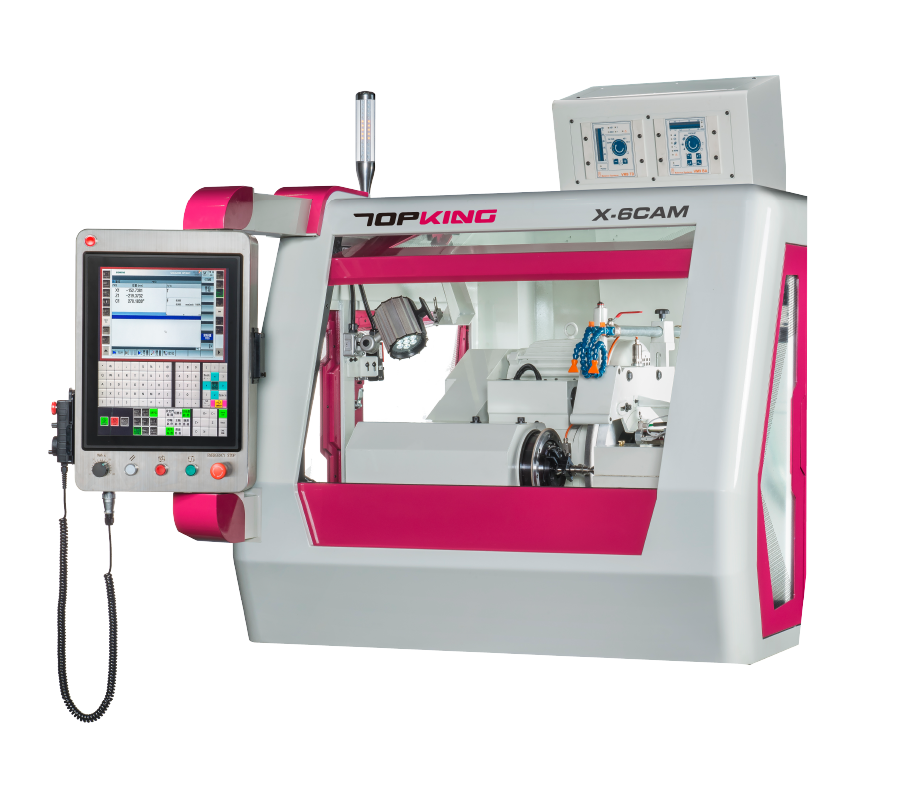

CNC CAM grinding

X-6CAM

CNC CAM grindingINTRODUCTION

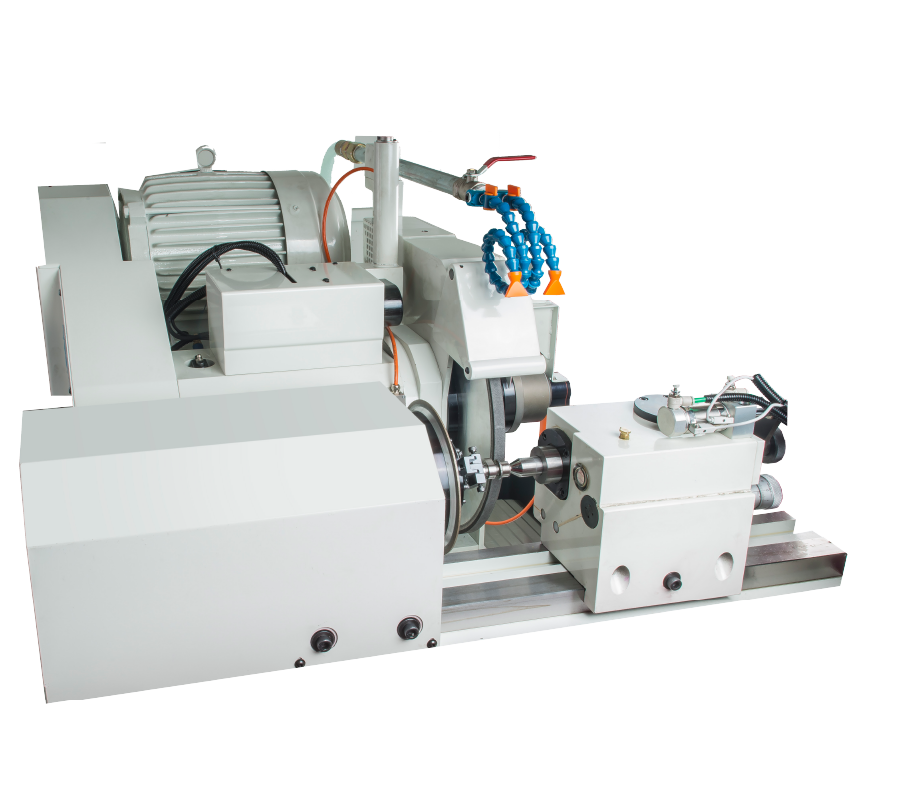

TOPKING's X-CAM series is the specialized design for eccentric and not circular components grinding. It’s applied to eccentric, cam shaft, crank shaft, polygon punch grinding. It’s especially suitable for use in the automotive, automation equipment, mold industries. Control system equips with advanced SIEMENS controller and cooperates with TOPKING latest GUI work interface, increase parameter setting efficiency. Providing the best accuracy performance and operating environment.| CAPACITY

Swivel Over Table: Ø230 mm

Distance Between Center: 270 mm

Max. Grinding Dia.: Ø200 mm

Max. Grinding Length: 150 mm

MACHINE FEATURE

USER FRIENDLY OPERATION SYSTEM

■ Equipped with SIEMENS 840Dsl control system. Built-in TOPKING’s latest version graph conversational operate interface includes crankshaft and camshaft grinding application. Make work easier! Moreover, operating with CAD/CAM software (optional accessories) easy to programming the custom-made grinding graphics. Provide a flexible and humanized operating environment.

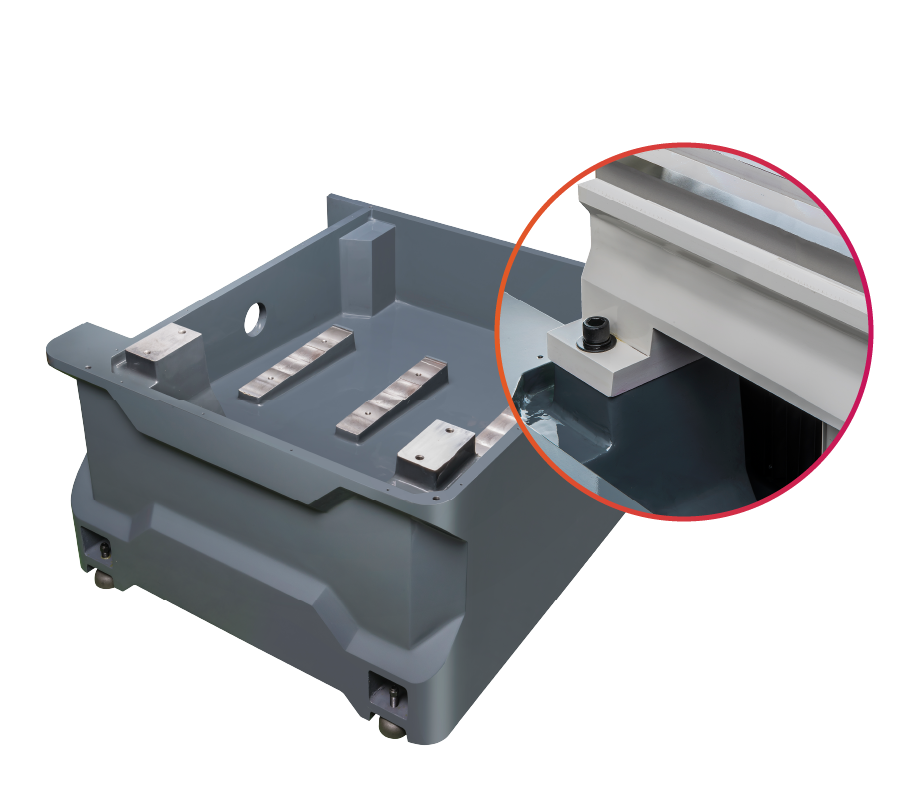

RIGID MACHINE BASE

■ Artificial granite machine base for excellent damping characteristics and favorable thermal behavior.

■ Machine covers the small mounting area. Get the utmost out of your working space.

WORK TABLE

■ The work table is permanently bolted to the machine. The cross-slide design is adopted to reduce travel. It can improve working speed and precision stability.

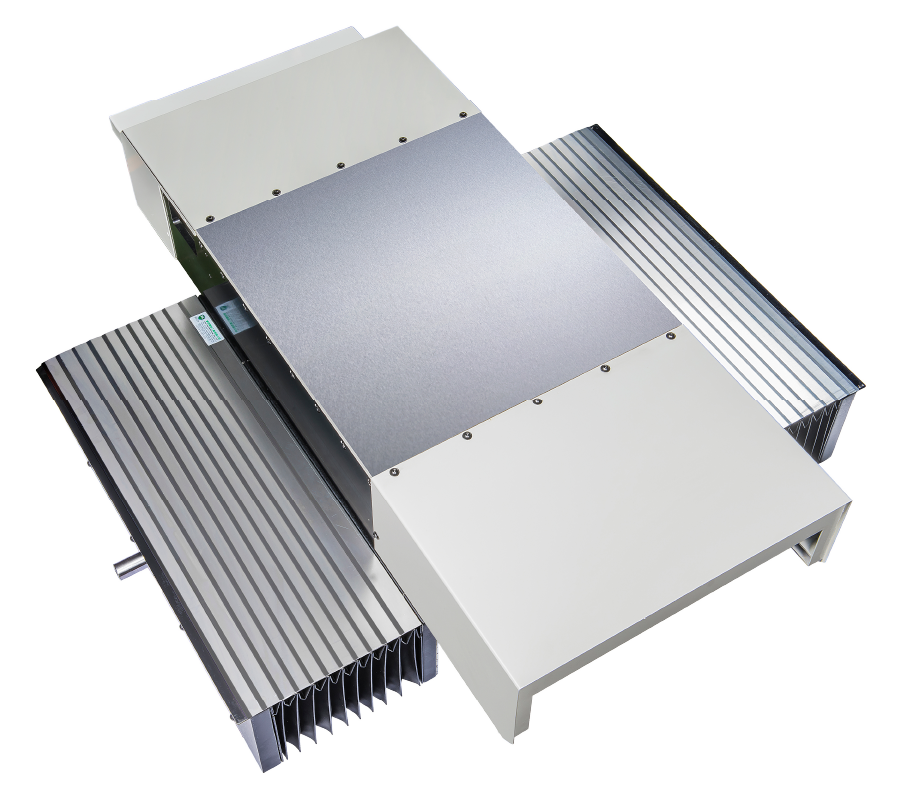

CROSS-SLIDER DESIGN & AXIS GUIDANCE

■ X and axes are designed as cross-sliders to reduce machine space.■The X-axis is driven directly by a linear motor, combined with linear guides, to achieve smooth axial movement. Equipped with a high-resolution linear scale as standard, ensuring stable repeatability precision and guaranteeing utmost precision during the machining process.

■ Two axes covered by enclosed telescopic covers. To protect the transmission structure and prevent contamination from grinding debris and coolant.

X-AXIS DRIVEN BY LINEAR MOTOR

■ X axis is driven by a linear motor directly, with no backlash for achieving more precise position control.

■ Cross-slider construction with high-speed precision linear motor and closed-loop control linear scale on X axis. Apply the smoothest working condition with the C axis.

■ Moving speed could reach 15000 mm/Min.

■ Linear motors constitute of coil and permanent magnets. No attrition for longer uses life and contributes to energy savings and increased efficiency.

WHEELHEAD CONSTRUCTION

Built-in spindle for grinding wheel.

■ The lightweight design of the wheelhead seat mitigates resonances stemming from conventional transmission components, thereby stabilizing the grinding process and elevating machining precision.

■ Built-in spindle proficiently manages and monitors spindle temperatures, effectively safeguarding against thermal deformation issues.

■ Built-in spindle's high-speed rotation and rapid response to acceleration and deceleration enable the fulfillment of speed adjustments and consistency required for intricate contour grinding.

■ Built-in spindle offers lower energy consumption and reduced pollution emissions, achieving benefits in energy efficiency and environmental conservation.

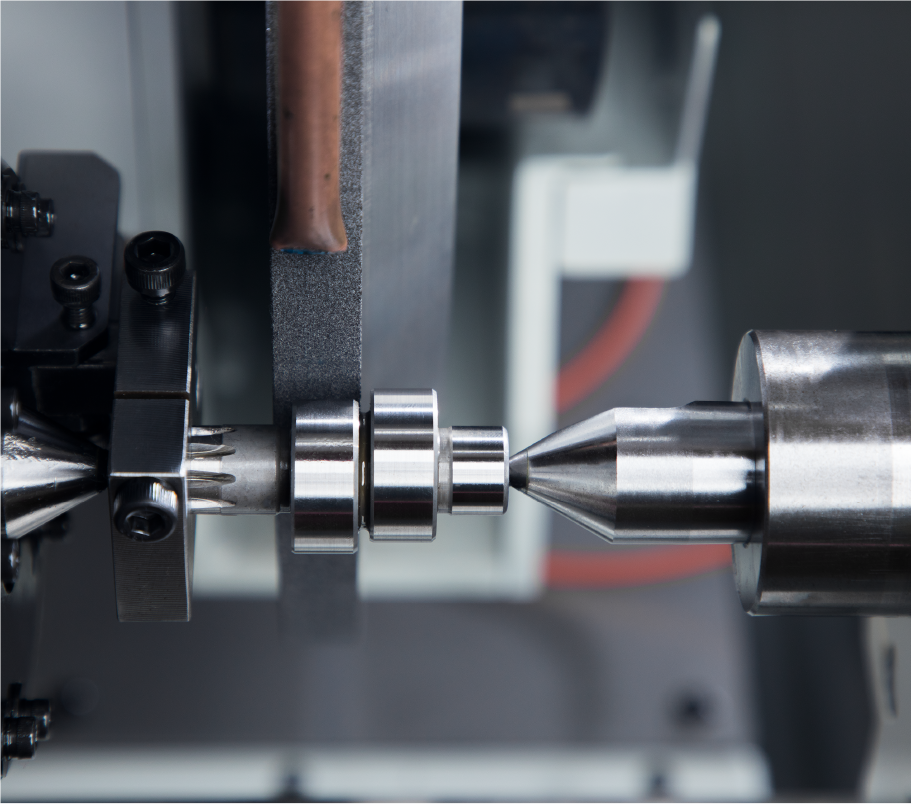

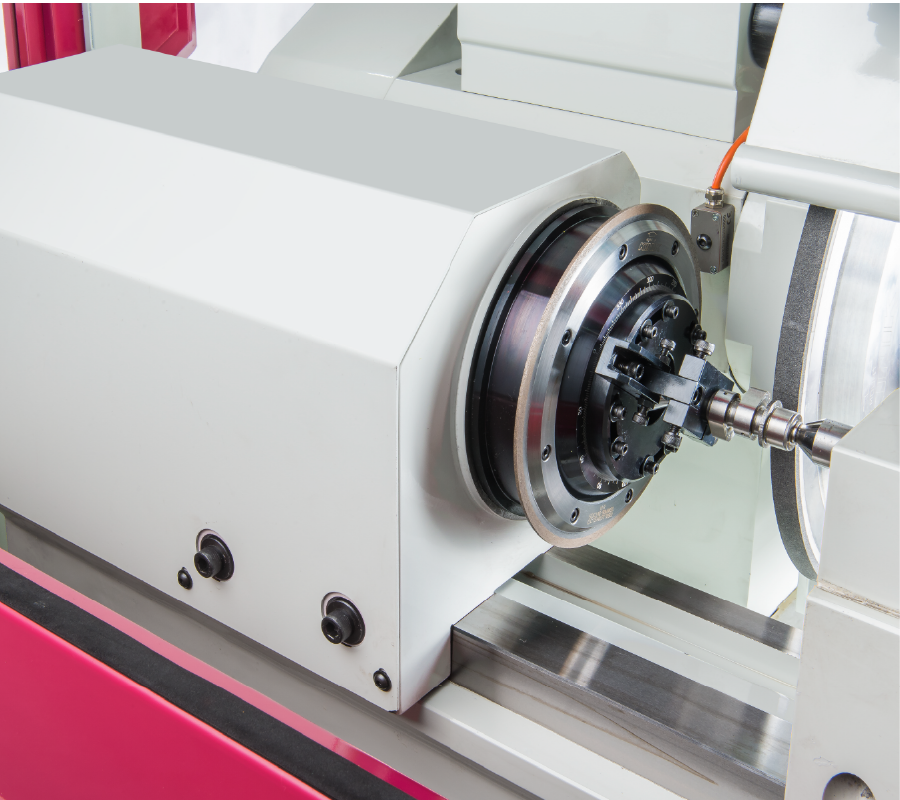

WORKTABLE

■ Working spindle equipped with a Direct Drive motor and precision angle encoder. High resolution of angle tolerance control ±0.2”. Accurate angle control applies for various eccentric, cam shaft, crank shaft, and polygon punch grinding.

■ Could do micro-adjustment for taper correction.

FINE ADJUSTMENT TAILSTOCK

■ An auto. oil bath lubrication system has been provided for tailstock to maintain high-level accuracy.

■ The oil level gauge provides a quick check of the oil level.

■ Could adjust enables taper correction in centers fixed grinding way.

AUTO. LIFT-UP SLIDING DOOR

■ Convenient automatic lift-up sliding door, which can reduce manual work and increase convenience

SPECIFICATION

| Capacity | |

|---|---|

| Swing Over Table | Ø230 mm |

| Distance Between Centers | 270 mm |

| Max. Grinding Diameter | Ø200 mm |

| Max. Grinding Length | 150 mm |

| Max. Load Held Between Centers | 5 kg |

| Center Height (from table to center tip) | 125 mm |

| Grinding Wheel | |

| Size (O.D. x width x I.D.) | Ø510 x 50 x Ø127 mm |

| Linear Velocity | 45 m/sec |

| Worktable | |

| Swiveling Angle | Fixed Type |

| Workhead | |

| Swiveling Angle | Fixed Type |

| Center Tapper | MT. No. 3 |

| Spindle Speed | 10 ~ 300 rpm |

| Max. Load of Spindle (tool holder included) | 15 kgs (max. length: 150 mm) |

| Tailstock | |

| Center Tapper | MT. No. 3 |

| Center Moving | Manual type |

| Tailstock Stroke | 25 mm |

| Barrel Stroke | ±30 μm |

| Cylindricity with Micro Adjustment | ±0.03 mm |

| X-axis Travel | |

| Max. Travel | 210 mm |

| Rapid Feedrate Speed | 20000 mm/Min |

| Auto. Feeding Speed | 6000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Z-axis Travel | |

| Max. Travel | 260 mm |

| Rapid Feedrate Speed | 10000 mm/Min |

| Auto. Feeding Speed | 6000 mm/Min |

| Min. Feeding Setting | 0.001 mm |

| Drive Motors | |

| Grinding Wheel Spindle | 11.4 kW (built-in motor) |

| Workhead Spindle | 22.3 Nm (direct drive motor) |

| Wheelhead Feed X-axis | 610 N (linear motor) |

| Table Feed X-axis (servo motor) | 2.29 kW (servo motor) |

| Lubrication Hydraulic Motor | NIL |

| Hydraulic Pump | NIL |

| Coolant Pump | 0.18 kW |

| Tank Capacities | |

| Hydraulic Tank | 18L |

| Lubrication Tank (Guideway) | P-107 |

| Coolant Tank | 107 L |

| Machine | |

| Dimension | 1600 x 2120 x 1800 mm |

| Machine Weight | 4300 kg |

| Center Height (from floor to center tip) | 1150 mm |

* The mentioned specifications & dimensions are subject to change without notice.

ACCESSORIES

STANDARD ACCESSORIES

■ CNC Controller (Brand: SEIMENS 840Dsl) x 1set

■ Grinding Wheel and Flange x 1 set

■ Grinding Wheel Inverter x 1 set

■ Diamond Tool Holder (tailstock mounted type) x 1 set

■ Diamond Tool Holder (tailstock mounted type) x 1 set

■ Carbide Tipped Work Centers (2 pcs/set) x 1 set

■ Micro Adjustment Tailstock x 1 set

■ Linear Motor for X-axis x 1 set

■ Linear Scale for X-axis x 1 set

■ Rotary Scale for C-axis x 1 set

■ CAD-CAM Software Graphical Programming x 1 set

■ Electric System x 1 set

■ Fully Enclosed Splash Guard x 1 set

■ Hydraulic System x 1 set

■ Coolant System x 1 set

■ Oil Mist Collector x 1 set

■ Work Lamp x 1 set

■ Tools (Leveling pad) and Tool Box x 1 set

■ Cam-locked Driving Dogs

■ Work Holder (2pcs/set)

■ 2-point Steady Rest

■ Adjustable 3-jaw Scroll Chuck

■ Adjustable 4-jaw Scroll Chuck

■ Diamond roller dressing device (connecting with workhead by flange)

■ Diamond roller dressing device (tailstoke mounted type)

■ Air Cylinder Tailstock

■ Wheel Balancing Stand and Arbor

■ Auto. Grinding Wheel Balancer

■ Spare Grinding and Wheel Flange

■ Touch Probe Gauge

■ Gap Control

■ Customized Workpiece Drive Fixture

■ Magnetic Coolant Separator

■ Paper Filter